- "Once implanted, the cells in the 3D printed patch grow and proliferate, while the silk proteins degrade into amino acids — giving space for damaged part of the organ to regrow."

A team of scientists from one of India’s premier technical institute, IIT Guwahati, have created a 3D printing bioink with live cells using proteins from Muga silk, a variety of wild silk geographically tagged to the state of Assam in India. The team has applied for a patent for the bioink made from Muga silk protein.

This 3D printing bioink can be used to bioprinting of tissues, implants and even organs at relatively lower costs. The research may help bridge the gap between patients requiring organ implants and healthy donors.

Speaking on the development of the new bioink, Biman B Mandal’s from the IIT Guwahati’s Biomaterials and Tissue Engineering Laboratory said, “Bioprinting has come a long way… We are now able to recreate minute architecture down to the micron level, which conventional methods were not able to do before,”

Why Muga Silk for 3D printing bioink?

Muga is a wild variety of silk found particularly in the Northeastern states of India and especially in Assam.

As per Mandal, the polymer-based bioink has to have certain properties so that it not only supports live cells but also prevents live cells from getting damaged in the process of printing and the polymers should retain its properties throughout the printing process.

Speaking about the selection of Muga Silk, Mandal explained, “For tissue engineering applications, we are always looking for polymers which would allow the cells to stick to it, and also give a suitable space for cells to grow and proliferate faster. Generally, people use different types of polymers such as collagen. Scientists use chemicals to bind cells to these polymers. Muga silk has ‘attachment sites’ naturally available. This silk is abundantly found in India but not available in any other country.”

Mandal added, “If we compare the cost of this product with collagen — 10 grams of collagen will cost you over Rs 10,000, but 10 grams of silk will cost you something like Rs 2.”

He added that their process is much simpler than existing tissue engineering techniques. The team hopes that their research will pave the way for 3D printing fully-functional organ implants in the future.

According to a certain claims, the 3D printed structures can also have applications in checking toxicity of drugs, and artificial organs can further help reduce the need to test drugs on animals.

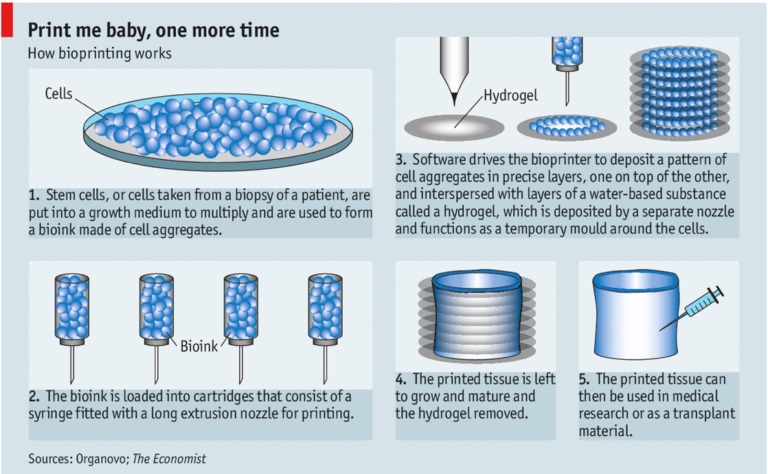

3D Bioprinting Process

The 3D bioprinting process starts with converting the patient data from MRI and CT scans to get a 3D model of the implant. Then the bioink is incorporated with stem cells from the patient. This bioink is used to 3D print artificial tissues. These artificial tissues and organs are then left to mature in a laboratory before being implanted to replace the defective body parts.

Once implanted, the cells in the 3D printed patch grow and proliferate, while the silk proteins degrade into amino acids — giving space for damaged part of the organ to regrow.

According to Mandal, “This method does away with the need for an additional surgery to remove the implant. When you use a 3D printer or bioprinter, the bioink should have specific properties.”

He added, “Liquid silk is used to create the 3D printing bioink. This is obtained either by dissolving silk fibres into appropriate solvents or by direct extraction from silkworm glands.”

Biman Mandal along with his team has been working with silk proteins to create artificial implants that mimic the biological architecture of real tissues and bone cartilage. His team has so far created prototypes of structural tissues such as bone, cartilage and knee-meniscus as well as soft tissues such as liver, heart and skin.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Indian Scenario page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.