Replique, a decentralised 3D printing platform provider for the secure and reliable production of industrial-grade parts, announced the launch of a comprehensive and open material database for 3D printing at Formnext. Replique is taking this step to make the collective material knowledge (with the help of its trusted material partners) available to the 3D printing community, ultimately streamlining the use of additive manufacturing (AM) for businesses.

For the first time, the new material database can be viewed at Replique’s booth in Hall 12.1, #A107.

Replique’s Open Material Database for 3D Printing at Formnext

The careful and informed selection of materials is critical for the success of additive manufacturing projects. However, so far, this research has been manual and labor-intensive. Replique’s material database now offers users an easy-to-use platform for selecting the best materials for their specific applications. Not only does this save time and money, but it also ensures the quality of additive manufactured components in terms of material requirements. Filtering options in the database include technical specifications, industry standards, and application fields.

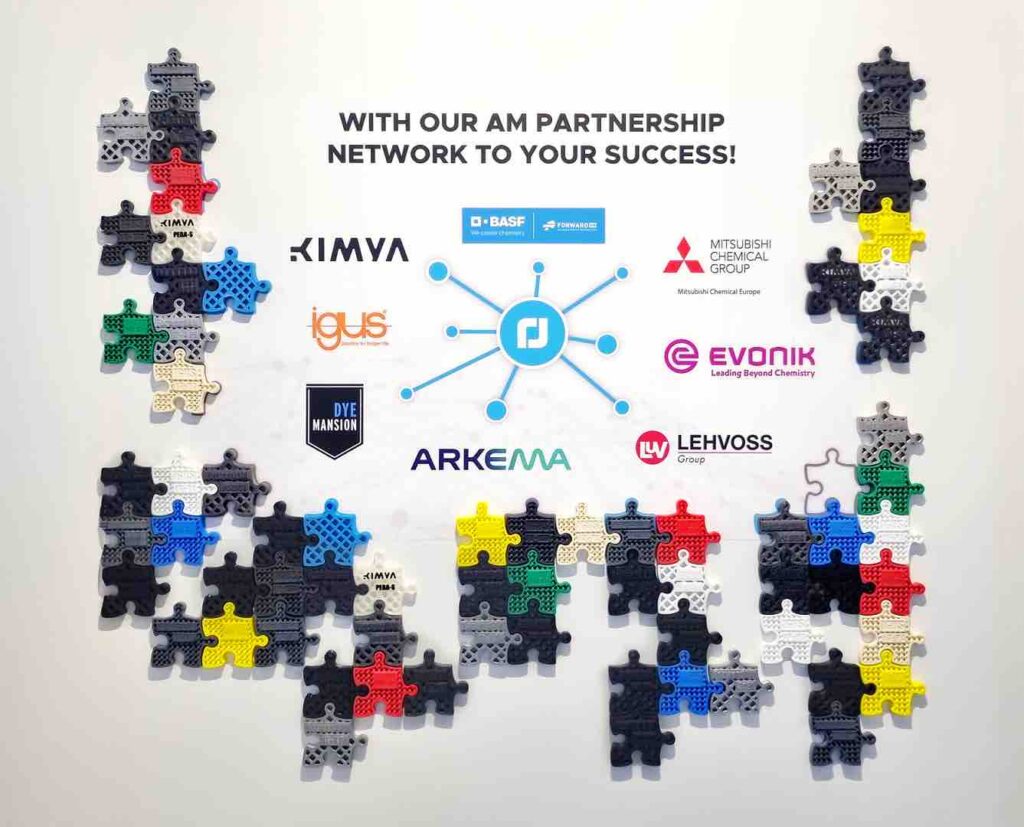

In the future, it will also provide quick access to reference cases and certificates, eliminating the need for time-consuming inquiries. This information is the result of partnerships formed with renowned material manufacturers over the last year.

“Through our daily engagement with material data, we have built a rich knowledge hub that we are now eager to share with the wider community. The launch of our material database represents another significant step in our mission to drive the industrialization of additive manufacturing and provide comprehensive support to our customers at every stage of their journey.”

– Dr. Henrike Wonneberger, CEO, and Co-Founder of Replique

Open design enables cross-platform usage of the database

The material database benefits more than just end users. Printer manufacturers, service providers, and other interested parties can also benefit from and contribute to the database, enriching their work and services with relevant information. The benefit stems from the database’s design as an open system. As a result, in the near future, the material data will be accessible not only through the Replique platform directly, but also through an API interface. For the convenience of all interested parties, all data will be accessible behind a free password barrier.

Replique is committed to expanding the platform further with additional services in the future. Dr. Max Siebert, CEO and Co-Founder of Replique, emphasized: “For all those looking to benefit from our platform or connect their own services, we are here to assist. Simply visit Replique’s booth at Formnext in Hall 12.1, Booth A107. We’re looking forward to exploring the huge potential of 3D printing together and shaping the future of this pioneering technology.”

The material database is an important component of Replique’s comprehensive ecosystem, which includes various services such as Additive Marking, which allows 3D printed parts to be traced. This comprehensive approach ensures that Replique users have easy access to all necessary information and services through a single central interface – the Replique platform.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.