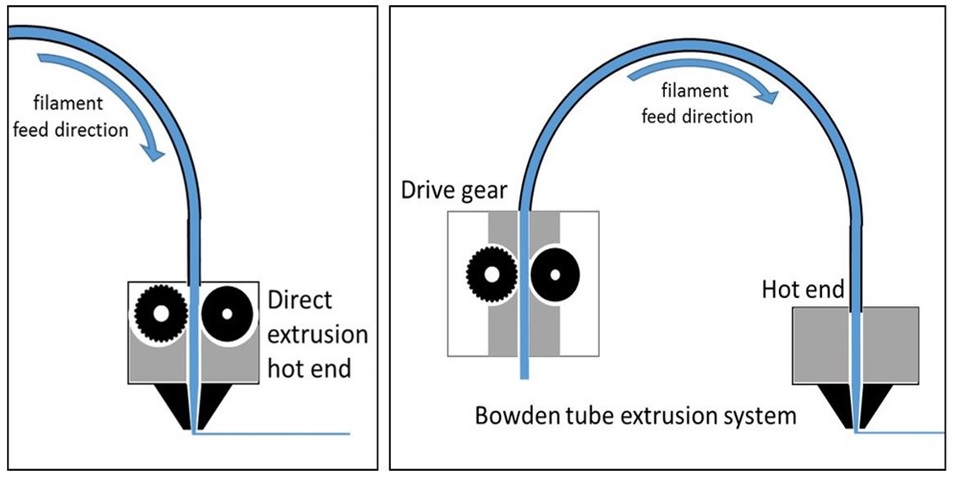

Fused Deposition Modelling (FDM) 3D printers use an extruder that is responsible for pushing the filament into a heater and nozzle assembly ultimately resulting in the deposition of the filament onto the build platform. This can either be a Bowden extruder or a Direct Drive Extruder.

While the ultimate purpose of both these systems is same, the assembly is slightly different. In a direct drive system, the extruder is mounted on the printhead which pushes the material directly into the nozzle. In a Bowden system, the extruder is mounted on to the printer frame and thus is at some distance from the nozzle. Thus the printhead receives the filament via a PTFE tube.

As explained, both systems perform the same function albeit with a slight variation and this variation induces some advantages and some disadvantages into the printing process impacting the performance of the 3D printer.

This begs the question, which extruder is better – The Bowden Extruder or a Direct Drive Extruder? Well, let’s have a look at both these systems and decide.

Bowden Extruder or a Direct Drive Extruder

Bowden Extrusion System

In contrast to a direct drive extrusion system, the extruder in a Bowden system is attached to the printer’s frame. It drives filament into the hot end by forcing it through a long PTFE tube (also known as a Bowden tube). This system, of course, has both benefits and drawbacks.

Pros

- Better Print Performance: As the extruder in a Bowden system is mounted on the printer’s frame instead on the printhead, the printhead is lighter and thus prints faster and quieter.

- Better Reliability: The absence of the extrusion system on top of the nozzle, ensure better reliability of the printing system. It also becomes more durable for long-term usage as the weight does not bog down the nozzle, the rails and is bound to deliver consistent results over a longer period of time than a direct drive system.

- Less Vibrations: The light weight also aids in reducing the vibrations in the system. This helps in better prints.

Cons

- Greater motor power: In a Bowden system, the filament is pushed to the printhead from a distance. Additionally, the movement of the filament through the PTFE tube creates friction. Both these factors mean you need a more powerful motor with more torque to control the filament.

- Slower response time: Because of the friction between the tube and the filament, there is a noticeable delay between the extruder and the nozzle. These extruders require faster acceleration in extrusion and retraction to deposit efficiently and avoid stringing.

- Material issues: The use of PTFE tube restricts the materials that can be used to print parts in Bowden systems. Flexible materials are not efficiently pushed through the tube, making the use of materials such as TPU/TPE is almost impossible. Abrasive filaments can also cut and bruise the tube if used frequently. This restricts the use of metal fill, fiber-filled materials, and other composites.

Direct Extrusion System

In a direct extrusion setup, the extruder pushes the filament directly into the nozzle. This certainly eliminates some drawbacks of the Bowden system, but it also has some of its own problems. Let us look at its advantages and disadvantages.

Pros

- Extrusion reliability: Because the printhead has a direct extruder attached to it, the motor can easily push filament through the nozzle, resulting in minimal extrusion issues.

- Better retraction: As against the Bowden style, the extruder is right above the printhead. This closeness to the nozzle, enables easy, faster and efficient retraction.

- Less powerful motor: Because of the short distance between the extruder and printhead and the elimination of PTFE tube causing friction, the motor requires less torque to push the filament.

- Increased filament variety: Direct extruders can also print a wider variety of filaments, most notably flexible and abrasive filaments. While flexible filaments can be printed with Bowden extruders, Direct extruders are more efficient. This is due to the fact that a Direct extrusion system is more constrained.

Cons

- Weight Issues: As the extruder is mounted on top of the printhead, the printhead becomes heavy and causes vibrations. The added weight also reduces its speed, produces jerky movements while changing directions and possibly loss of print accuracy in horizontal movements.

- Maintenance issues: Maintenance can be difficult in some direct extrusion setups because the extruder is attached to the printhead, making access to specific parts for maintenance more difficult.

Final Thoughts

So, which systems is better you ask? Well, any system you use, be it a Bowden Extruder or a Direct Drive Extruder, both have its own advantages and disadvantages. The choice completely depends on a few factors that you should consider before making a decision.

Stability: The first is the frame’s and motion system’s stability. Many delta printers, for example, cannot withstand the weight and vibrations of a direct extruder. If your Cartesian or CoreXY printer has a sturdy structure, printing with a direct extruder should be no problem.

Print Speed: Print speed is also an important factor to consider. If you want to print quickly and precisely with standard materials, a Bowden extruder setup will be more suitable.

Material Range: Consider the materials you intend to print with. A direct extrusion system is probably the best option if you want to use flexible or abrasive filaments on a regular basis.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.