Nano Dimension Ltd., one of the leading additive electronics providers unveiled a new SOLIDWORKS add-in to its DragonFly 2020 Pro 3D Printer. This add-in has made possible to 3D print electronics in a single build process thereby making 3D printing of complex prototypes made of polymers and metals designed in SOLIDWORKS easier when compared with the traditional editing software for 3D printed electronics.

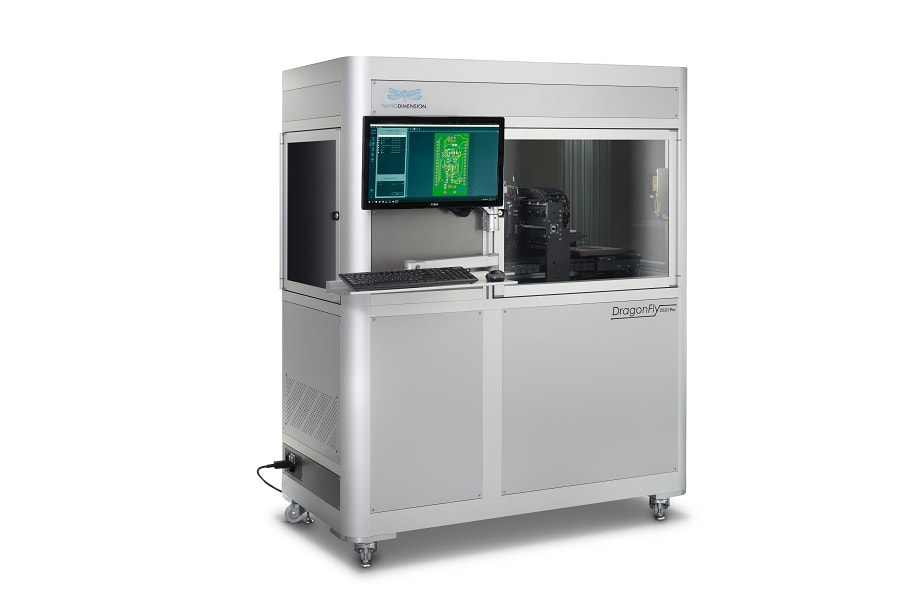

Above: The DragonFly 2020 Pro 3D Printer/Image Credit: Nano Dimension

Unveiled at the ongoing SOLIDWORKS World 2018 event in Los Angeles, the new add-in is being said to mark a significant advancement in how electronics are designed in SOLIDWORKS. For example, the new add-in offers several advantages over conventional editing software for 3D printed electronics. Earlier, designers used to find it difficult to edit and print 3D print designs that contain conductors. However, the new add-in has now made it possible for designers to print such designs without leaving SOLIDWORKS.

By combining conductive and insulating materials in a single 3D print, the add-in has eased the process of creating 3D printed complex geometric structures with embedded electronics, encapsulated sensors, encapsulated sensors, and antennas. The new add-in makes it possible for users to easily point-and-click to subdivide an object, and then automatically select conductive or insulating materials for different bodies of the object and 3D print.

The add-in is also said to not only increase design possibilities to allow users develop more capable products, but also reduce the cost of errors when creating complex, geometric parts. Such feature, the company believes can greatly help in accelerating product design as well as fasten time-to-market.

Providing more details of how the new add-in can benefit designers, Suchit Jain, Vice President of Strategy & Business Development, SOLIDWORKS, Dassault Systèmes, said, “By 3D printing electronics, designers can obtain faster prototypes and work on PCBs in 3D, not just 2D”. “With Nano Dimension’s SOLIDWORKS add-in, for the first time ever users can design and 3D print electronics with a push of a button. We are proud to be partnering with an industry innovator like Nano Dimension,” Jain added.

Explaining more about how the new add-in for SOLIDWORKS applications was created, Simon Fried, President of Nano Dimension USA stated in an official release, “We developed this add-in for SOLIDWORKS applications as a direct response to our customers’ needs for prototyping increasingly complex designs”. “The SOLIDWORKS add-in for the DragonFly 2020 Pro is the first tool to enable the combination of freeform objects and embedded 3D electronics. This capability offers our customers the ability to make what is currently unmakeable. This enables new ways of thinking, new ways of designing and ultimately, providing revolutionary solutions to some of today’s toughest product design challenges,” Fried added.