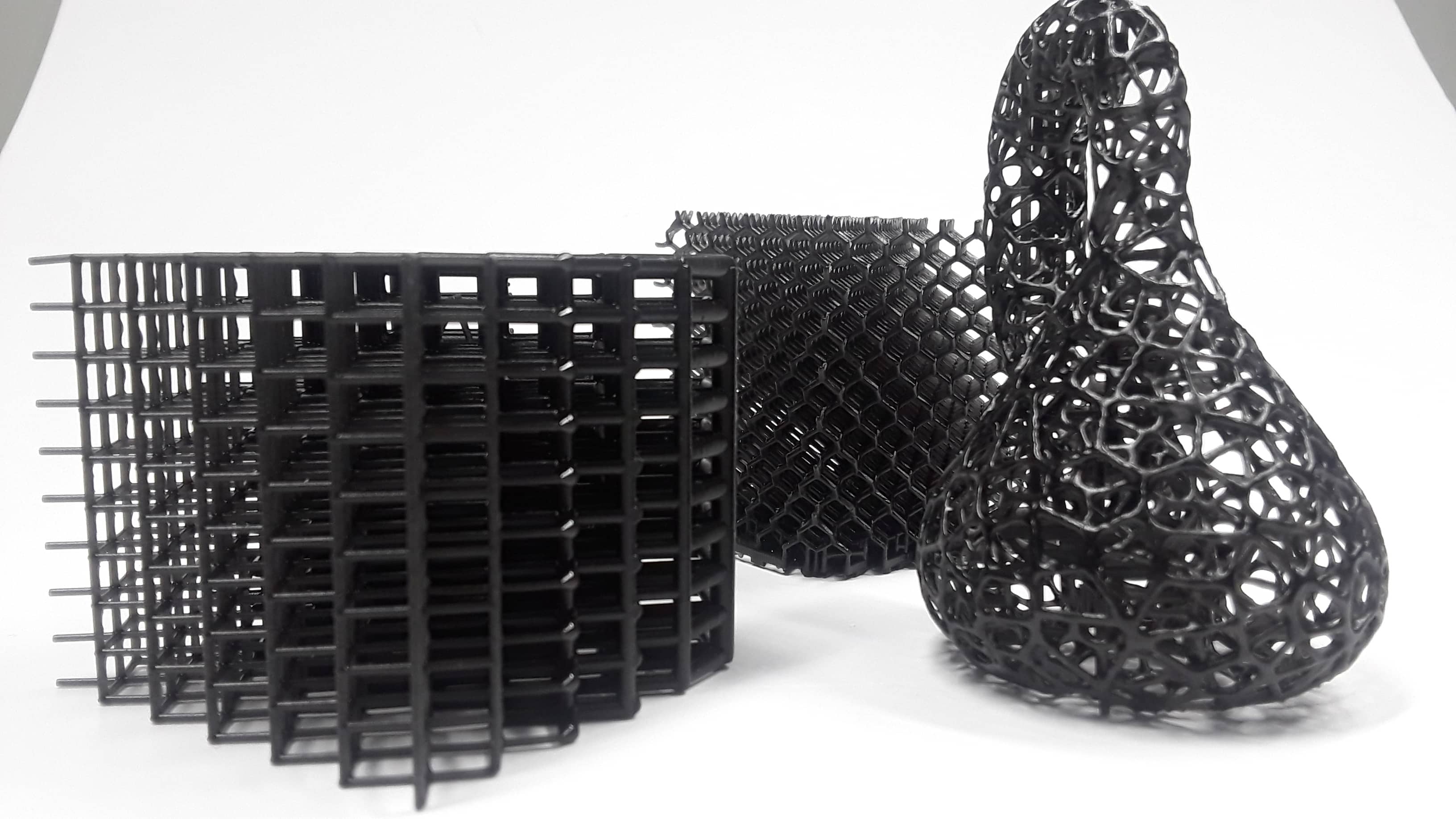

Above: A Resin part from Splitvision/Image Credit: PostProcess Technologies

PostProcess Technologies Inc., the first and only provider of automated and intelligent post-printing solutions for industrial 3D printing, recently announced a collaboration with Splitvision, an international industrial design agency, to streamline their workflow and improve working conditions for post-printing of their Digital Light Processing (DLP) 3D printing.

Founded in 1989, Splitvision implemented additive manufacturing into their workflow in 2019 with the purchase of a Figure 4 DLP printer, which instantaneously improved their additive process efficiencies, as well as the mechanical properties and fine feature details of their prototypes. However, without an automated post-printing system, Splitvision encountered many bottlenecks, including excess labor, to effectively clean intricate parts, and concerns regarding the smell and flammability of IPA.

With the implementation of PostProcess Technologies’ Resin Removal solution and proprietary detergent specifically developed for that system, Splitvision significantly reduced their post-printing cycle times, improved resin removal consistency, and now enjoy an overall safer, and more pleasant environment. A recently published case study outlines the dramatic improvements to their process. Individual parts previously requiring up to 30 minutes each for resin removal are now processed in batches of many parts at once in 4 to 5 minutes with the PostProcess technology.

[penci_related_posts taxonomies=”undefined” title=”You Might Also Like to Read” background=”” border=”Orange” thumbright=”yes” number=”4″ style=”grid” align=”none” displayby=”cat” orderby=”random”]

Speaking to the efficiencies achieved with the PostProcess Technologies solution, Lukass Legzdins, R&D Director at Splitvision, said, “We now can offer printed parts at a reasonable price, especially when we print multiple items in one run. Plus, the nasty bit of the printing process has been eliminated for our staff. After having tried the PostProcess solution, it’s hard to imagine ever going back to using IPA.”

“From the software to the chemistry to the hardware, our focus is on providing a full-stack solution to revolutionize the way that customers post-print for a better additive manufacturing workflow. It is invigorating to see companies like Splitvision benefitting from the use of PostProcess technology,” said Bruno Bourguet, Managing Director, PostProcess Technologies.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.