Firestorm Labs, a leader in expeditionary manufacturing, has secured $47 million in Series A funding to expand its innovative warfront factory-in-a-box manufacturing system. The funding round was led by New Enterprise Associates (NEA) with participation from notable defence-focused investors including Lockheed Martin Ventures, Decisive Point, Washington Harbour Partners, and Booz Allen Ventures, among others. The package includes $12 million in venture debt from J.P. Morgan.

This substantial investment builds upon Firestorm’s initial $12.5 million seed round and reflects growing confidence in the company’s approach to distributed factory-in-a-box manufacturing for defence applications. The funding will enable Firestorm to advance its additive manufacturing platform by expanding its engineering team, opening a larger production facility, and broadening its partnership program.

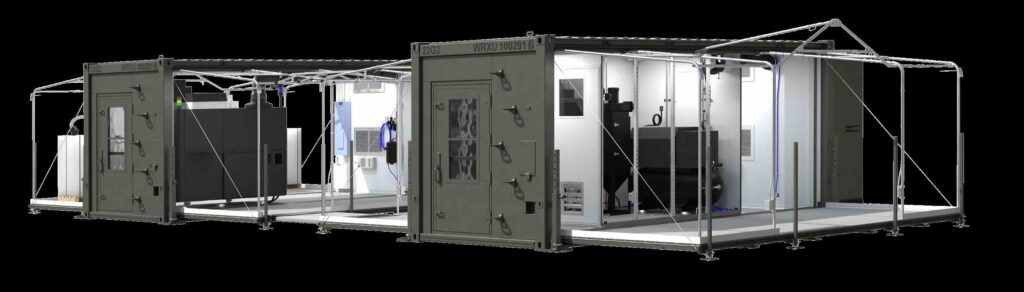

Scaling the xCell Factory-in-a-box Manufacturing System

At the heart of Firestorm’s innovation is the xCell system, a complete factory-in-a-box manufacturing solution that enables production of mission-critical components directly at the point of need. This expeditionary platform allows combat units to produce complete Tempest Unmanned Aerial Systems (UAS) on-site and reconfigure them for various missions including intelligence, surveillance, reconnaissance (ISR), electronic warfare, or strike operations.

The factory-in-a-box manufacturing approach addresses a critical military challenge: the need to replenish losses and adapt drone fleets in contested environments without returning systems to centralised facilities or waiting for spare parts. By enabling on-site 3D printing of modular airframes and components, Firestorm’s technology dramatically reduces production timelines, costs, and logistical constraints.

“We’re thrilled about this milestone, because it empowers Firestorm to deliver critical, battlefield-ready solutions faster and at scale. Our unique ability to 3D print modular airframes on-site dramatically reduces production timelines, costs, and logistical constraints, giving the U.S. and allied forces the adaptive technology they urgently need in complex and contested operational environments.”

– Dan Magy, CEO of Firestorm Labs

Strategic Importance of Factory-in-a-box Manufacturing for Defence

The investment aligns with Executive Order 14307, “Unleashing American Drone Dominance,” which calls for rapid field production and sustainment of unmanned systems. Industry leaders have emphasized the strategic importance of Firestorm’s factory-in-a-box manufacturing approach to defence readiness.

According to Chris Moran, vice president and general manager of Lockheed Martin Ventures, “Our military needs technology it can trust to be ready when the circumstances demand it. Deployable, on-site 3D drone printing is a powerful tool that further extends the warfighter’s ability to secure the battlespace, while advancing U.S. leadership on the frontiers of defence technologies.”

Military leadership has also recognised the operational impact of Firestorm’s capabilities. U.S. Army Gen. Richard D. Clarke (Ret.), who recently toured Firestorm’s San Diego facilities, remarked, “As a former senior commander focused on supply chains and reducing long logistics tails, I know amateurs talk tactics, professionals talk logistics. Firestorm’s innovation is really helping that logistics chain to operate more efficiently.”

Enhancing Modular Factory-in-a-box Solutions

The funding will allow Firestorm to enhance its factory-in-a-box modularity suite by uniting an onboard computer, tactical software, developer tools, and mission planning into one plug-and-play ecosystem. Unlike laboratory prototypes, this operator-first solution is field-proven and delivers autonomy, adaptability, and control at the edge without vendor lock-in or reliance on GPS or communications.

“Firestorm continues to deliver ground-breaking innovations, building the future of autonomous systems to meet the needs of full-spectrum combat operations,” said Thomas Hendrix, general partner at Decisive Point. “The combination of edge manufacturing, modularity in vehicles and payloads, and high-volume/low-cost production pathways has been quickly recognized as a force multiplier and operational necessity by various organizations across the DoD.”

This investment supports the Department of Defence’s prioritisation of logistics resilience including modularity, point-of-need manufacturing, and seamless planning-to-production workflows. The technology empowers non-technical personnel to launch complete build cycles in contested environments and shifts sustainment control back to front-line units.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.