Following its public debut at Formnext 2025, Anycubic recently announced the opening of the deposit program for Kobra X, a new entry-level FDM 3D printer designed to make multi-colour and multi-material printing more accessible to a broader range of users.

Unveiled alongside the company’s latest product line-up in Frankfurt, Kobra X reflects Anycubic’s continued focus on simplifying advanced desktop manufacturing workflows.

Kobra X positions itself within this strategy as an open-frame, single-nozzle multicolour printer aimed at users entering multi-colour printing for the first time, without requiring external colour support devices or complex system integration.

Kobra X – Entry-Level Multicolor FDM 3D Printer

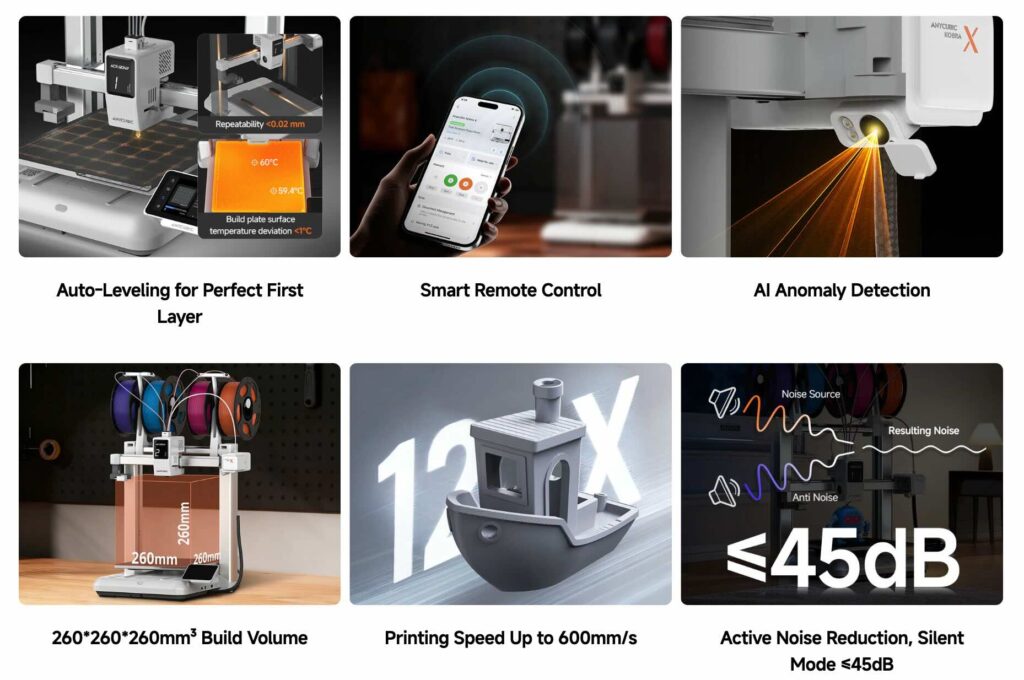

At the core of Kobra X is Anycubic’s second-generation ACE (Anycubic Colour Engine) architecture, which integrates four filament channels directly into the printhead and shortens the molten filament transition path to approximately 30 mm. Compared with external filament-swapping systems that rely on long retraction distances, this design allows colour changes to occur over a much shorter travel range, improving efficiency during multicolour prints with frequent transitions.

In controlled internal tests using common 4-color models, Anycubic observed that ACE GEN2 can reduce colour-switching time by approximately 30–50%, while lowering filament purge waste by a similar margin. Although results vary depending on model geometry, material combinations, and transition frequency, the shorter molten filament path generally enables faster, more material-efficient colour changes in everyday multicolour printing scenarios, while preserving a single-nozzle workflow familiar to entry-level users.

Practical Multi-Material Capability: From PLA to TPU and PVA

Beyond colour, Kobra X is designed to support multi-material printing within the same job. Through adaptive extrusion pressure control, the system can switch between materials with different mechanical properties, including combinations such as PLA with TPU (68D) or PLA with PVA.

This capability allows users to explore functional designs—such as flexible joints, soft-touch components, or soluble supports—without moving to dual-extrusion systems or enclosed industrial platforms. By keeping material switching within a single-nozzle architecture, Kobra X maintains a relatively straightforward setup while extending the range of applications available to entry-level users.

Kobra X is intended to be approachable for first-time multicolour users, while incorporating the standard hardware and firmware features expected from modern desktop FDM printers. These include automated bed levelling, motion and flow calibration, AI-assisted print monitoring, quiet operation modes, and a streamlined assembly and maintenance workflow.

Deposit Program Now Open

As of December 26, Anycubic has opened the deposit program for Kobra X via its official store. Customers can place a US$10 deposit, which will be applied as a US$30 discount toward the final purchase price at checkout.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.