EOS, one of the leading 3D printing companies, has announced that its popular EOS Aluminium AlSi10Mg powder is now produced using 100% recycled feedstock. This development marks a significant advancement in sustainable materials for metal additive manufacturing, with the company reporting a 77% reduction in carbon dioxide emissions compared to its previous formulation and an 83% reduction when compared to AlSi10Mg made from virgin raw materials.

The move builds upon EOS’s earlier sustainability efforts that began in April 2024, when the company first included this aluminium alloy in its Responsible Products portfolio by incorporating 30% recycled content. Despite the switch to fully recycled materials, EOS confirms that the powder maintains identical properties, characteristics, and performance in printed parts, eliminating the need for existing customers to requalify their applications.

EOS Aluminium AlSi10Mg Specs and Environmental Benefits

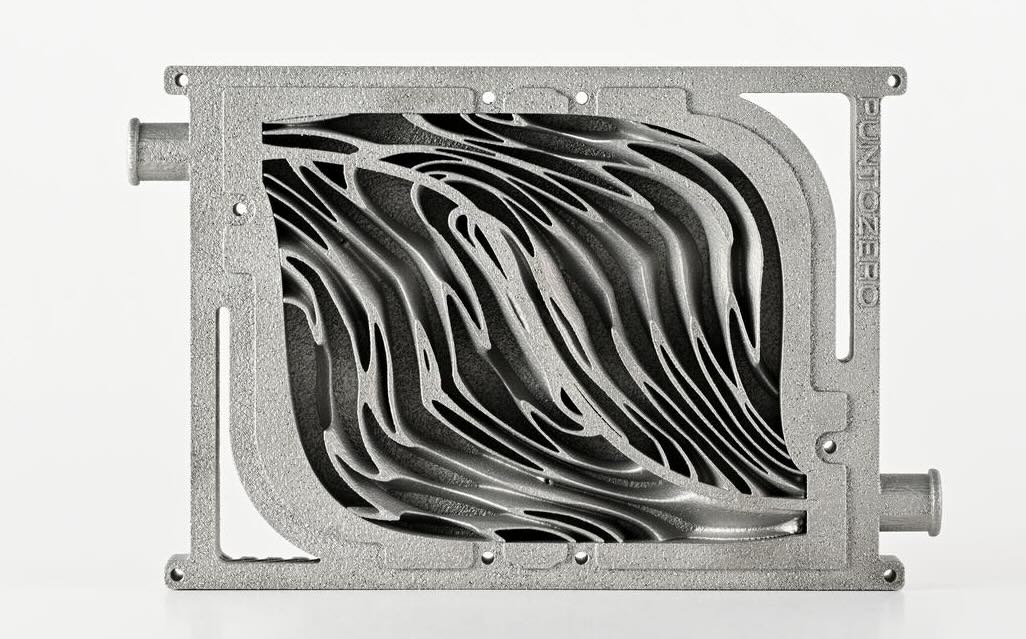

The fully recycled EOS Aluminium AlSi10Mg maintains the same technical specifications that have made it a popular choice for industrial applications. The material delivers an ultimate tensile strength of 460 MPa, yield strength of 245 MPa, and 5% elongation at break, making it suitable for structural components that require both strength and some ductility.

The aluminium alloy offers good thermal and electrical conductivity and remains compatible with post-process heat treatments. These properties make it appropriate for applications in aerospace, automotive, and general engineering where weight reduction and performance are critical factors.

From an environmental perspective, the shift to 100% recycled feedstock represents a substantial reduction in carbon footprint. The 77% decrease in CO2 emissions compared to the previous formulation demonstrates the significant environmental gains possible through material sourcing changes, even when the final product specifications remain unchanged.

Sophia Heyl, Product Specialist at EOS, expressed pride in this achievement: “We’re proud to have developed our first EOS metal material made with 100% recycled feedstock and to have achieved so much in less than a year. We will continue to explore ways to reduce the carbon footprint of our customers’ applications with every EOS product – from materials and hardware to design optimisation – they all add up to a more responsible end-use product for our customers and the climate.”

Part of a Broader Sustainability Strategy

The introduction of fully recycled aluminium powder forms part of EOS’s larger sustainability initiative, which includes several other product offerings designed to reduce environmental impact across the additive manufacturing workflow.

The company’s VIRTUCYCLE programme exemplifies this approach by providing a take-back service for used polymer materials and components. Through this programme, EOS reclaims used powder and transforms it into recycled high-performance injection moulding granules using sustainably sourced energy.

Other offerings in the EOS Responsible Products portfolio include PA 1101, which the company describes as a “climate-neutral” polymer material. This biobased material has its greenhouse gas emissions offset through carbon credits. Similarly, PA 2200 CarbonReduced polymer materials achieve lower greenhouse gas emissions by utilising green energy in their production process.

To help customers understand and manage their environmental impact, EOS has also developed the Carbon Calculator. This tool considers additive manufacturing project carbon emissions alongside key cost metrics, providing organisations with estimates of their carbon dioxide emissions and expenses related to 3D printing operations.

Björn Hannappel, head of sustainability at EOS, emphasised the company’s ongoing commitment: “We are continuing our path towards Responsible Manufacturing and expanding our portfolio of Responsible Products stepwise. By minimising waste, reducing the environmental footprint and prioritising eco-friendly materials, organisations can both protect our planet and create a more efficient and resilient business model.”

Availability and Pricing

EOS has stated that there will be no price difference for the new 100% recycled aluminium powder compared to its predecessor, making the environmental benefits available without additional cost burdens for customers. This pricing strategy removes potential financial barriers to adoption and encourages the transition to more sustainable materials.

The fully recycled EOS Aluminium AlSi10Mg is currently available for purchase through the EOS Store or by contacting the EOS Life Cycle Solutions team directly. The material is compatible with existing EOS metal 3D printing systems and process parameters, allowing for straightforward implementation into current production workflows.

For manufacturers already using EOS Aluminium AlSi10Mg, the transition to the recycled version offers an immediate opportunity to reduce the environmental impact of their additive manufacturing operations without compromising on part quality or performance.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.