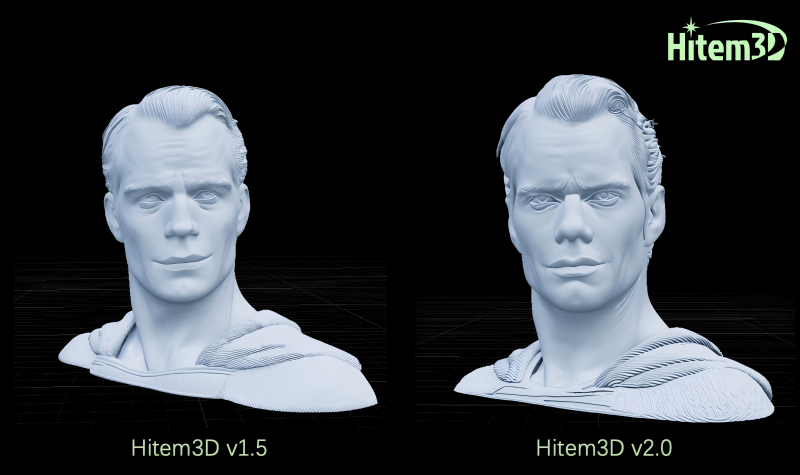

HiTEM3D 2.0 has been released with integrated capabilities designed to address the persistent problem of 3D printing texture generation that has challenged the industry for years. Developed by Math Magic in Hong Kong, the new platform introduces structure-aware texture generation at 1536³ Pro resolution, aiming to transform how AI-generated 3D models transition from digital renders to physical prints.

The release tackles a fundamental issue in additive manufacturing workflows where traditional geometry-first approaches create textures that appear convincing on screen but fail during physical production. The classic methodology of building mesh structures before projecting surface details has long resulted in stretched textures, mismatched seams, missing detail in hidden areas, and extensive manual correction before models can be safely sent to printers.

Integrated Approach Addresses Production Workflow Failures

For years, 3D pipelines have operated with a compromise where geometry defines shape whilst textures are applied afterwards as separate layers. This separation becomes problematic when models move beyond visual renders into manufacturing applications. When transitioning to physical output, the traditional workflow generates predictable failures including texture distortion at curved surfaces, incomplete coverage in occluded regions, and structural inconsistencies that only become apparent during printing.

A HiTEM3D technical lead explained the development focus: “We’re focused on making the structure, texture, and production logic more coherent because if generation isn’t solid, printing and mass production turns into rework.” The platform’s approach synchronises texture generation with geometric reconstruction rather than treating them as sequential steps. This structure-aware method ensures textures maintain consistency with underlying geometry throughout the model, including areas not visible in standard preview angles.

3D Printing Texture Generation Technology

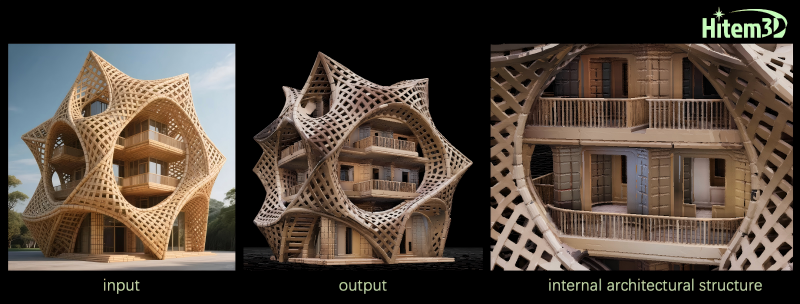

HiTEM3D 2.0 generates texture information during the geometry reconstruction phase, providing consistent completion across both visible and occluded regions. In architectural applications tested by 3D printing studios, the system filled interior walls, inner faces of openwork structures, and balcony railings with consistent material and texture logic. These areas typically collapse into blank spaces in traditional workflows, only revealing problems during physical printing.

One studio operator noted that models appearing acceptable from front views exposed critical issues during production. “Before, a model could look fine from the front, but printing exposed the issues: empty bottoms, missing interior surfaces. Now the completion happens during generation, and we can send it to print with far fewer fixes,” the operator stated.

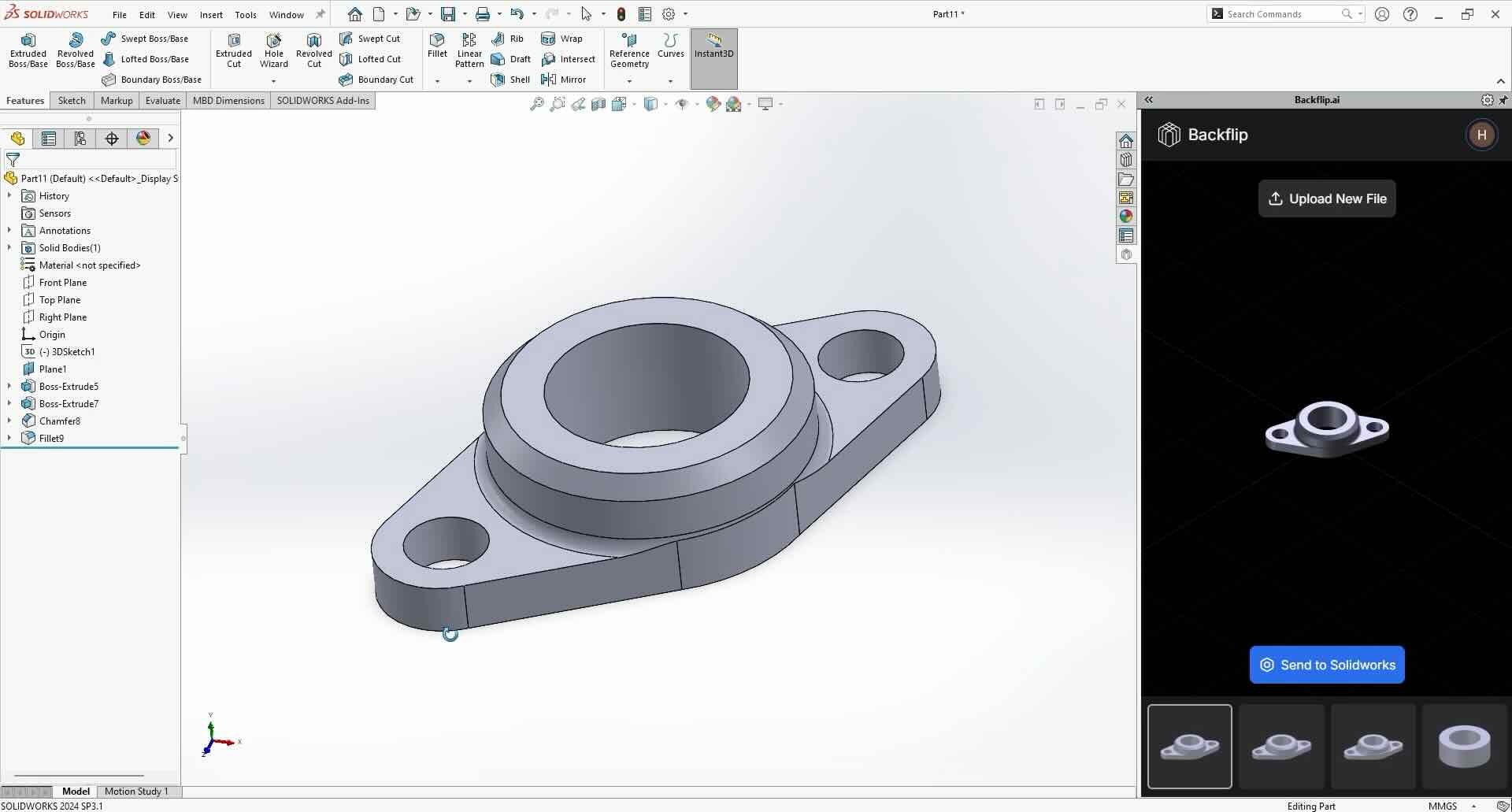

The platform employs intelligent 3D semantic segmentation to comprehend internal component logic, automatically exporting four-colour print-ready assets. Combined with automated retopology and AI-driven 3D embossing, the system bridges what the company describes as the “last mile” from algorithmic generation to manufacturing specifications. This approach aims to deliver deterministic output where digital previews accurately represent physical results.

The technology addresses specific failure points that have historically required manual intervention. For elongated structures with complex curves, traditional algorithms typically produce texture stretching, misalignment, and distortion at sharp transitions. HiTEM3D 2.0’s spatial continuity processing maintains physical logic across layered features, avoiding the fusion of recessed crevices or texture stretching on inner surfaces that characterise conventional approaches.

The platform extends beyond generation capabilities with deep Blender integration, transforming into a native productivity tool within digital content creation workflows. Support for USDZ formats and advanced geometry-plus-image texture synthesis allows enhancement of existing asset libraries. The system exports models in GLB, OBJ, FBX, and STL formats for compatibility across mainstream modelling software and printing applications.

Math Magic positions the release as addressing the gap between demonstration-quality AI outputs and repeatable production capability. The company acknowledges that real-world testing beyond curated examples will determine whether the platform delivers on its production-ready promise across the full variety of geometries, joint complexities, and occlusion scenarios encountered in professional manufacturing environments.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.