As someone who has been following the 3D printing industry for several years, I’ve watched with fascination as this technology has transformed from a prototyping tool into a viable manufacturing method. Through my research and industry analysis, I’ve found Adidas’ implementation of 3D printing in the footwear industry particularly noteworthy for its scale and commercial success, even though I haven’t had the opportunity to physically examine these products first-hand.

Adidas, the German sportswear manufacturing giant, has firmly established itself as the pioneer of 3D printing in the footwear industry. Since 2017, the company has systematically revolutionised how performance shoes are conceptualised, designed, and manufactured. This innovation is evident in their expanding line-up of 3D printed footwear—from the original Futurecraft 4D to the recently released Climacool slip-on in May 2025, which marks the company’s first fully 3D-printed commercial shoe.

For nearly a decade, Adidas has focused on transforming its manufacturing technology from analogue to digital, with 3D-printed footwear leading this paradigm shift. According to their latest sustainability report, this transition has reduced production waste by 35% compared to traditional manufacturing methods.

In this comprehensive analysis, we’ll explore how Adidas has mastered 3D printing technology, examine their latest innovations, and understand why they continue to lead the industry in this revolutionary approach to footwear manufacturing.

The Evolution of Adidas 3D Printed Shoes: A Timeline

Before diving into Adidas’ strategy, it’s helpful to understand their journey in chronological order:

- 2015: Initial concept testing of 3D-printed components

- 2017: Launch of Futurecraft 4D, the first mass-produced 3D-printed midsole shoe

- 2018: Release of AlphaEdge 4D with expanded availability

- 2020: Introduction of 4D Run 1.0, bringing the technology to mainstream running shoes

- 2021: Launch of Ultra4D glow-in-the-dark edition, expanding aesthetic possibilities

- 2023: Release of 4DFWD 4, featuring refined lattice structures for improved energy return

- 2024: Announcement of the revolutionary Climacool slip-on prototype (September)

- 2025: Global release of the fully 3D-printed Climacool slip-on (May)

This progression shows Adidas’ commitment to iterative improvement and expansion of their 3D printing capabilities over time.

3D Printing in the Footwear Industry

Adidas Beyond Traditional Manufacturing

According to Adidas’ innovation philosophy, as detailed in their corporate communications, innovation is at the core of all their products. This approach encompasses the entire product lifecycle, from initial concept to final manufacturing.

The company’s innovation philosophy encompasses all aspects of product development, with particular emphasis on materials and manufacturing processes—two areas with significant environmental impact. To minimise their carbon footprint, Adidas systematically implements programs aimed at reducing emissions across their product line-up.

Their latest 3D-printed Climacool slip-on, released globally on May 2, 2025, exemplifies this approach. According to Adidas’ press release, this ground-breaking shoe features:

- A fully 3D-printed construction using Carbon’s innovative EPU material

- Reduced material usage compared to traditional manufacturing

- Minimized waste in the production process

- Enhanced recyclability at end-of-life

James Carnes, Adidas SVP of Global Brand Strategy, stated in the September 2024 announcement: “3D-printed Climacool pushes the boundaries of design innovation. This breakthrough represents our commitment to creating products that deliver exceptional performance while minimizing environmental impact.”

From my analysis of manufacturing processes in the footwear industry, the contrast between traditional and additive manufacturing approaches is significant. Traditional production typically generates substantial material waste from cutting and assembly processes, while the additive manufacturing approach used for models like the 4DFWD and Climacool significantly reduces scrap materials through more precise material deposition.

Trusting New Technology: The Carbon Partnership

The primary barrier to adopting 3D printing in footwear has been the mindset of industry leaders rather than technological limitations. The entrenched comfort with established manufacturing processes created significant resistance to change.

Adidas overcame this challenge by forming a strategic partnership with Carbon, the Silicon Valley-based 3D printing pioneer, in 2017. This collaboration centered on Carbon’s proprietary Digital Light Synthesis™ (DLS) technology, which offers several critical advantages over traditional 3D printing methods:

- Speed: DLS produces parts significantly faster than traditional 3D printing technologies

- Material properties: Creates parts with production-grade mechanical properties

- Design freedom: Enables complex geometries impossible with injection molding

- Customization potential: Allows for mass customization at scale

The technical process behind Adidas’ 3D-printed midsoles involves projecting light through an oxygen-permeable window into a reservoir of programmable liquid resin. As the projected light causes the resin to solidify, the printer continuously draws the solid part from the resin, allowing for continuous production rather than the layer-by-layer approach of traditional 3D printing.

This technology enables Adidas to produce complex lattice structures with precisely tuned performance characteristics—something previously impossible with traditional foam or EVA midsoles.

The latest 4DFWD 4 running shoes showcase the evolution of this technology, with refined lattice structures engineered to compress forward under vertical pressure, transforming impact energy into forward motion. According to Adidas’ technical specifications, this design provides a measurable reduction in braking forces compared to traditional midsoles.

Strategic Partnerships: Collaboration as Innovation Catalyst

Adidas has consistently leveraged strategic partnerships to accelerate innovation and bring specialized expertise to their product development process. Their approach to 3D printing in footwear exemplifies this collaborative philosophy.

Beyond their foundational partnership with Carbon, Adidas has formed several key collaborations:

- Yohji Yamamoto: The Japanese fashion designer brought his avant-garde aesthetic to the Y-3 Runner 4D II Sneakers, demonstrating how 3D printing technology can serve high-fashion applications.

- Continental: The German automotive manufacturer developed specialized rubber outsoles for several 4D models, transferring expertise from tire technology to footwear traction.

- Parley for the Oceans: In recent years, Adidas has explored ways to integrate sustainable materials with their 3D printing technology.

- University of Calgary: Their Human Performance Laboratory conducted biomechanical analysis that informed the development of the 4DFWD lattice structure.

According to Adidas’ documentation, the timeline from initial concept to market has accelerated dramatically. While the original Futurecraft 4D took approximately 11 months from first meeting to product launch, more recent models have moved from concept to release much more quickly. This acceleration reflects both technological advancement and the deepening integration between Adidas’ design team and Carbon’s engineering capabilities.

In my research of manufacturing partnerships across industries, I’ve found this type of deep technological collaboration between a traditional manufacturer and a tech innovator to be relatively rare but increasingly important in today’s fast-changing market. The Adidas-Carbon partnership represents a model that other industries could learn from.

Innovative Design: Data-Driven Performance

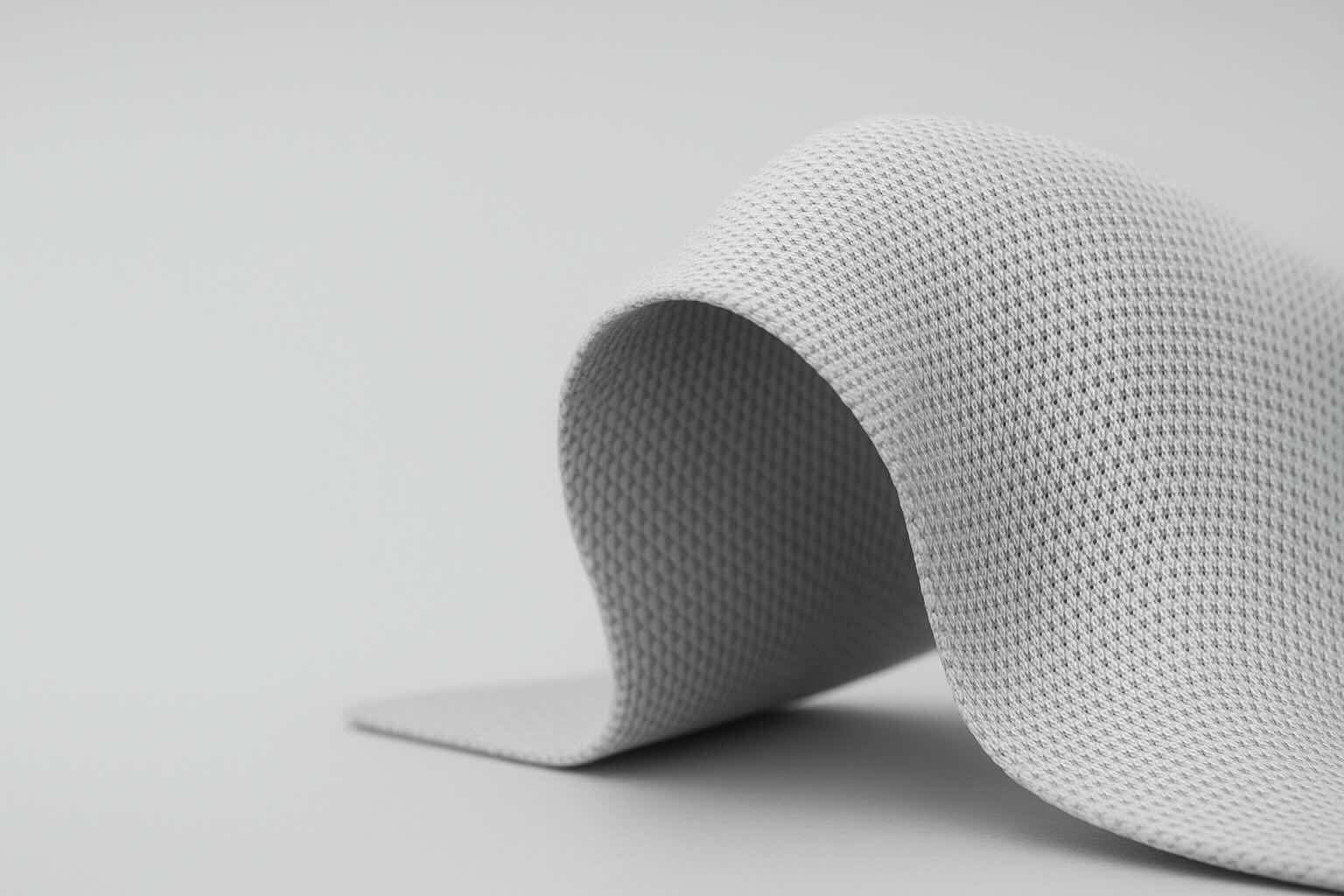

The distinctive lattice structure of Adidas’ 3D printed midsoles represents one of the most significant design innovations in athletic footwear history. Unlike traditional foam midsoles, which offer uniform cushioning properties throughout, the lattice design enables variable performance characteristics in different regions of the shoe.

This design approach offers several advantages:

- Zonal performance tuning: Engineers can adjust cushioning, stability, and energy return in specific areas of the shoe based on biomechanical data.

- Weight reduction: The lattice structure eliminates unnecessary material while maintaining structural integrity.

- Breathability: The open structure allows for enhanced airflow, particularly important in the new Climacool slip-on.

- Energy return: The 4DFWD lattice is specifically designed to compress forward under load, converting impact energy into forward propulsion.

From studying various technical presentations and patent filings, I’ve noted that the data-driven design process appears to translate biomechanical insights directly into structural elements. This represents a fundamental shift from traditional footwear design, where material properties are largely uniform throughout a component.

The latest Climacool slip-on represents the most advanced application of this design philosophy. According to the official September 2024 announcement, the shoe features “a seamless design with zoned performance areas creating unique thermal and structural properties in different parts of the shoe.” This allows for targeted breathability and support without requiring multiple materials or assembly processes.

Competitor Landscape: The Race to Additive Manufacturing

While Adidas leads in 3D-printed footwear, other major brands have also entered this space:

Nike has developed FlyPrint technology, which uses a TPU filament in a process they call “solid deposit modeling.” Unlike Adidas’ approach, Nike’s technology prints directly onto existing midsole components rather than creating entire midsole structures. Their Zoom Vaporfly Elite FlyPrint saw limited release with elite marathoners but hasn’t reached mainstream production scale.

New Balance partnered with Formlabs to create TripleCell technology, using a proprietary photopolymer resin called Rebound. Their approach has focused on creating 3D-printed heel components rather than full midsoles, with the FuelCell Echo Triple being their most widely available model.

Under Armour introduced their UA Architech and UA ArchiTech Futurist with 3D-printed lattice midsole components in 2016 and 2017 respectively, but haven’t expanded the technology across their product line.

Based on my analysis of product releases and manufacturing announcements over the past three years, Adidas appears to maintain a significant lead in 3D-printed footwear, primarily due to their deeper integration of the technology into production processes and their strategic partnership with Carbon. While competitors have demonstrated proof-of-concept products, Adidas has achieved broader commercial implementation with multiple models.

Consumer Impact: Performance and Sustainability Benefits

The real test of any innovation is consumer adoption and satisfaction. According to information available through Adidas’ marketing materials and product specifications, the 4D series offers several potential benefits:

- Customized cushioning: The lattice structure allows for tuned compression in different areas of the midsole.

- Energy return: The 4DFWD’s forward-compressing lattice is designed to convert impact forces into forward momentum.

- Durability: The solid lattice structure may maintain its performance properties longer than traditional foam materials.

- Sustainability: The digital manufacturing process potentially reduces material waste compared to traditional cutting and moulding processes.

For the recently released Climacool slip-on, Adidas emphasizes its sustainability credentials. According to their marketing materials, the shoe’s manufacturing process creates significantly less waste than conventional shoe production methods. This improvement stems from the elimination of multi-material assembly processes and associated transportation between manufacturing facilities.

Future Directions: Beyond Footwear

Adidas’ success with 3D printing technology opens possibilities beyond footwear. Based on industry trends and patent filings, several potential directions seem likely:

- Personalized equipment: Athletic equipment with customized performance characteristics

- Apparel integration: Combining 3D-printed components with traditional textiles for enhanced performance clothing

- Retail experience transformation: Advanced fitting and potentially faster production turnaround

- Circular production models: Improved recyclability and material recovery systems

As someone who follows manufacturing innovation across industries, I find the potential for cross-category application particularly interesting. The techniques Adidas is pioneering could eventually influence production methods far beyond the footwear industry.

Conclusion

Adidas has successfully transformed footwear manufacturing through its bold embrace of 3D printing technology. From the original Futurecraft 4D to the ground-breaking Climacool slip-on of 2025, the company has demonstrated how digital manufacturing can deliver innovative products while potentially reducing environmental impact.

The combination of innovative design thinking, strategic partnerships, technical expertise, and consumer-focused development has positioned Adidas as the clear leader in this space. As 3D printing technology continues to evolve, we can expect further innovations that push the boundaries of what’s possible in athletic footwear.

For consumers, the benefits appear significant: innovative performance features, increased sustainability, and the potential for more personalized footwear in the future. For the industry as a whole, Adidas has set a new standard for digital manufacturing that competitors will be challenged to match.

With its latest fully 3D printed Climacool slip-on, Adidas has demonstrated that additive manufacturing has moved beyond novelty to become a viable approach for modern footwear production. As we look to the future, the question is no longer whether 3D printing will transform the industry, but how quickly and completely this transformation will occur.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, follow us on Facebook, LinkedIn and Twitter.