Researchers at MIT’s Computer Science and Artificial Intelligence Laboratory have released MechStyle, a system that addresses a critical limitation in AI-driven design where generative AI personalises 3D printed objects without compromising structural integrity. The breakthrough tackles the persistent problem of visually appealing AI modifications that result in physically weak products once fabricated.

Traditional generative AI tools for 3D design prioritise aesthetics over mechanical durability, creating models that appear perfect on screen but fail under real-world stress. MIT Department of Electrical Engineering and Computer Science PhD student Faraz Faruqi led the development of MechStyle alongside collaborators from Google, Stability AI, and Northeastern University to bridge this gap between digital creativity and physical reliability.

Generative AI Personalises 3D Printed Objects Safely

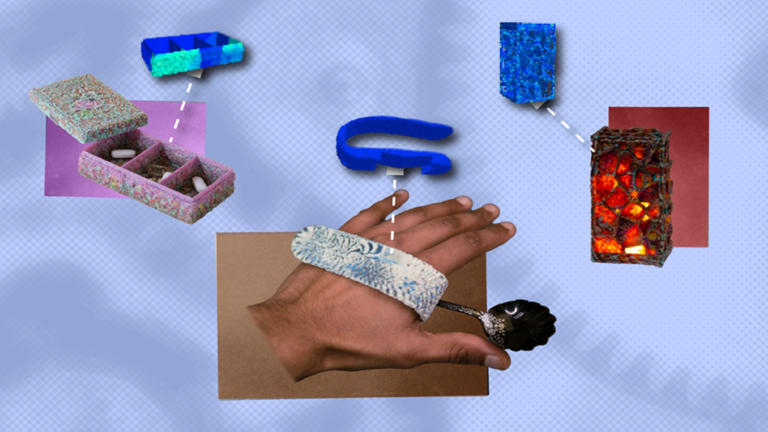

MechStyle integrates finite element analysis directly into the design workflow, monitoring how AI-generated geometric changes affect structural performance. The system allows users to upload existing 3D models or select preset assets such as vases, wall hooks, or pillboxes, then customise them using text or image prompts whilst continuously assessing mechanical viability.

When a user selects a wall hook model and prompts the system to “generate a cactus-like hook,” the AI reshapes the geometry to resemble a cactus whilst preserving load-bearing capacity. The simulation module works alongside the generative model, identifying vulnerable regions and adjusting the stylisation process to maintain strength. This ridged, organic-looking hook can then support mugs, coats, and backpacks just as effectively as a standard design.

The research team tested 30 different 3D models with styles resembling bricks, stones, and cacti to determine optimal approaches for maintaining structural viability. They found that dynamically identifying weak regions and tweaking the generative AI process produced the most reliable results. The system employs two strategies: completely halting stylisation when stress thresholds are reached, or gradually implementing smaller refinements to prevent at-risk areas from approaching failure points.

This represents a dramatic improvement over previous AI-based design systems. Formative research conducted by the MIT team revealed that only approximately 26 per cent of 3D models remained structurally viable after AI modification using conventional approaches. MechStyle achieved up to 100 per cent structural viability across tested models, demonstrating how physics-aware modelling fundamentally changes design outcomes.

“We want to use AI to create models that you can actually fabricate and use in the real world,” Faruqi explained. “MechStyle simulates how generative AI-based changes will impact a structure. Our system allows you to personalise the tactile experience for your item, incorporating your personal style into it whilst ensuring the object can sustain everyday use.”

Dual-Mode Design Balances Creative Exploration with Structural Safety

The platform offers two operational modes addressing different user needs. A freestyle feature allows rapid visualisation of various styles on 3D models without extensive structural analysis, enabling quick creative exploration. The MechStyle mode conducts careful structural impact assessment before finalising designs. Users can experiment with multiple aesthetic directions in freestyle mode, then switch to MechStyle mode to verify that artistic flourishes won’t compromise durability in specific model regions.

Rather than running computationally expensive simulations after every minor adjustment, MechStyle monitors where alterations occur and only rechecks physics when changes could compromise strength. This selective approach maintains design responsiveness whilst ensuring safety.

Applications span from decorative items to functional products including textured glasses, lampshades, and assistive medical devices such as finger splints and utensil grips. The system demonstrates particular value in medical making, where customisation often conflicts with safety requirements. Personalised assistive devices must fit individual users whilst maintaining sufficient strength to support daily activities.

Google Research Scientist Fabian Manhardt, who was not involved in the research, noted the significance of the achievement. “While style-transfer for 2D images works incredibly well, not many works have explored how this transfer to 3D. Essentially, 3D is a much more difficult task, as training data is scarce and changing the object’s geometry can harm its structure, rendering it unusable in the real world. MechStyle helps solve this problem, allowing for 3D stylisation without breaking the object’s structural integrity via simulation.”

The research team aims to extend MechStyle’s capabilities beyond modifying existing designs. Future versions would generate complete 3D models from scratch based on user descriptions, eliminating the need to locate existing models in online repositories. This would benefit users unfamiliar with 3D modelling or those seeking designs unavailable in current databases. If someone wanted to fabricate a unique bowl design not found online, the system could create it entirely from a text description whilst ensuring structural soundness.

The research was published in the ACM Symposium on Computational Fabrication. The work represents a crucial evolution in AI-assisted manufacturing, establishing new standards for personalised 3D-printed products where aesthetic freedom and physical feasibility coexist. Industries from home décor to medical devices stand to benefit as designers gain confidence that objects will perform reliably under everyday conditions whilst expressing individual style preferences.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.