Space 3D printing research reached a significant milestone on 24th August 2025 when NASA’s SpaceX 33rd commercial resupply mission successfully launched from Cape Canaveral Space Force Station in Florida. The Dragon spacecraft carried over 5,000 pounds of scientific equipment and experiments to the International Space Station, with multiple ground-breaking 3D printing investigations forming the centrepiece of this mission. The successful launch at 2:45 a.m. EDT marked another advancement in additive manufacturing capabilities for future long-duration space missions to the Moon and Mars.

Acting NASA Administrator Sean Duffy emphasised the mission’s importance for future space exploration, stating that the flight would “test 3D printing metal parts and bioprinting tissue in microgravity – technology that could give astronauts tools and medical support on future Moon and Mars missions.” The Dragon spacecraft docked autonomously at approximately 7:30 a.m. on 25th August to the forward port of the space station’s Harmony module, delivering critical research materials that will advance understanding of manufacturing capabilities in microgravity environments.

Delivering Space 3D Printing Research

The European Space Agency’s Metal 3D Printer investigation represents a crucial advancement in space 3D printing research, building upon the recent successful printing of the first metal parts in space. This experiment addresses the growing need for on-demand manufacturing capabilities as mission duration and distance from Earth increase, making traditional resupply methods increasingly challenging. The investigation will evaluate different printing strategies to determine optimal approaches for metal printing in space environments.

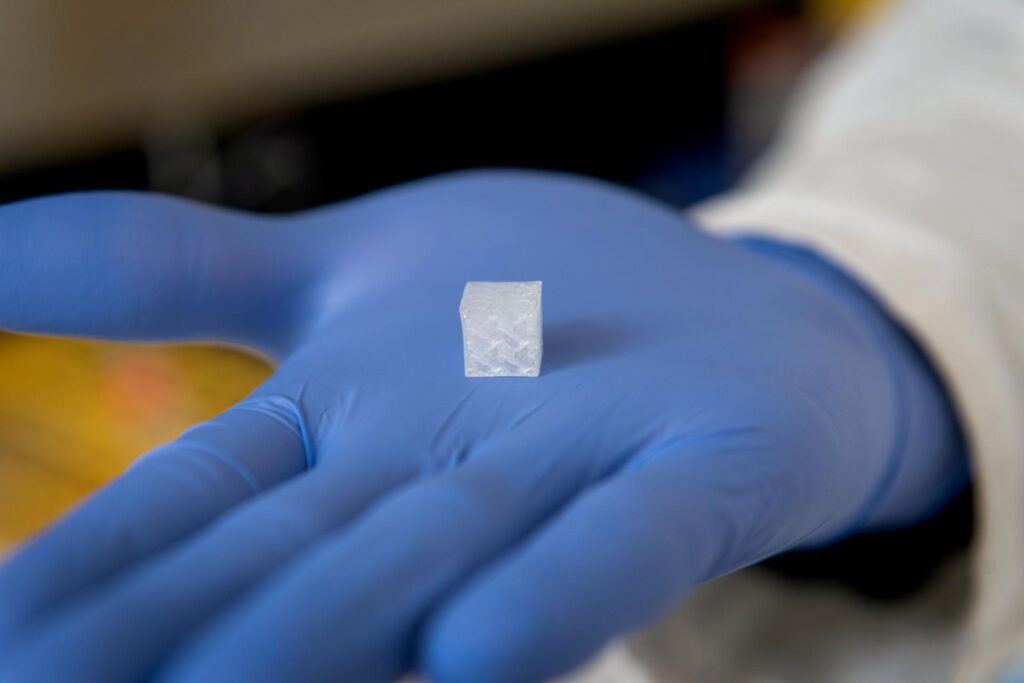

“We’ll print several small cubes using different strategies to help determine the optimal approach for metal printers in space, as well as two small nozzles to examine the quality of spacecraft parts printed in microgravity.”

– Rob Postema, ESA technical officer

The space-printed components will undergo rigorous quality comparison against reference prints manufactured on Earth, providing valuable data for future manufacturing applications in space.

The metal printing capabilities represent a significant evolution from previous plastic 3D printing successes aboard the space station. Whilst plastic printing has proven valuable for various applications, metal printing opens possibilities for creating critical spacecraft components, tools, and spare parts that require greater durability and strength. This technology could enhance mission autonomy by reducing dependence on Earth-based supply chains during extended lunar and Mars missions.

Revolutionary Bioprinting Advances Medical Research

The mission includes two ground-breaking bioprinting experiments that could transform medical treatment both in space and on Earth. The InSPA-Auxilium Bioprinter investigation aims to create implantable medical devices designed to support nerve regrowth after traumatic injuries. This research addresses the significant challenge of nerve gap injuries, where existing treatments provide limited restoration of nerve function and often result in impaired physical capabilities.

Jacob Koffler, principal investigator at Auxilium Biotechnologies, outlined the mission’s ambitious goals: “On this mission, we plan to print up to 18 of the implants and anticipate using them in preclinical studies on the ground in 2026 and 2027.” The research hypothesis suggests that tissues bioprinted in microgravity may achieve higher quality than those manufactured on Earth, potentially supporting future production of medical devices both for space crew members and terrestrial patients.

The second bioprinting experiment focuses on liver tissue development, examining how engineered liver tissues containing blood vessels behave in microgravity conditions. James Yoo, principal investigator at the Wake Forest Institute of Regenerative Medicine, explained the research objectives: “We are especially keen on accelerating the development of vascular networks in the tissue.” Previous missions established that bioprinted liver tissue could survive and function in space, but this investigation aims to determine whether microgravity actually improves tissue development processes.

The vascular network development research holds particular significance for long-term space missions and terrestrial medical applications. Successful acceleration of blood vessel development could support eventual production of functional organs for transplantation on Earth whilst providing crucial medical capabilities for astronauts on extended missions to the Moon and Mars.

Addressing Bone Loss Through Cellular Research

Complementing the 3D printing investigations, the mission includes critical research into bone loss prevention through the Microgravity Associated Bone Loss-B (MABL-B) experiment. This study examines bone-forming stem cells in microgravity to understand the fundamental mechanisms behind astronaut bone loss during spaceflight. Researchers have identified IL-6, a protein that signals stem cells to promote either bone formation or bone loss, as a potential therapeutic target.

“If we are successful, the compound also can be evaluated for the treatment of conditions associated with bone loss on Earth, such as osteoporosis and certain types of cancers.”

– Dr. Abba Zubair, principal investigator at the Mayo Clinic in Florida

This research exemplifies how space-based investigations can provide solutions for both space exploration challenges and terrestrial medical conditions.

The Dragon spacecraft’s extended stay at the International Space Station until December 2025 will provide ample time for these experiments to yield comprehensive results. The mission also included a successful reboost demonstration, with Dragon’s hardware performing orbital maintenance activities that help sustain the station’s altitude through a series of planned burns extending into autumn 2025.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.