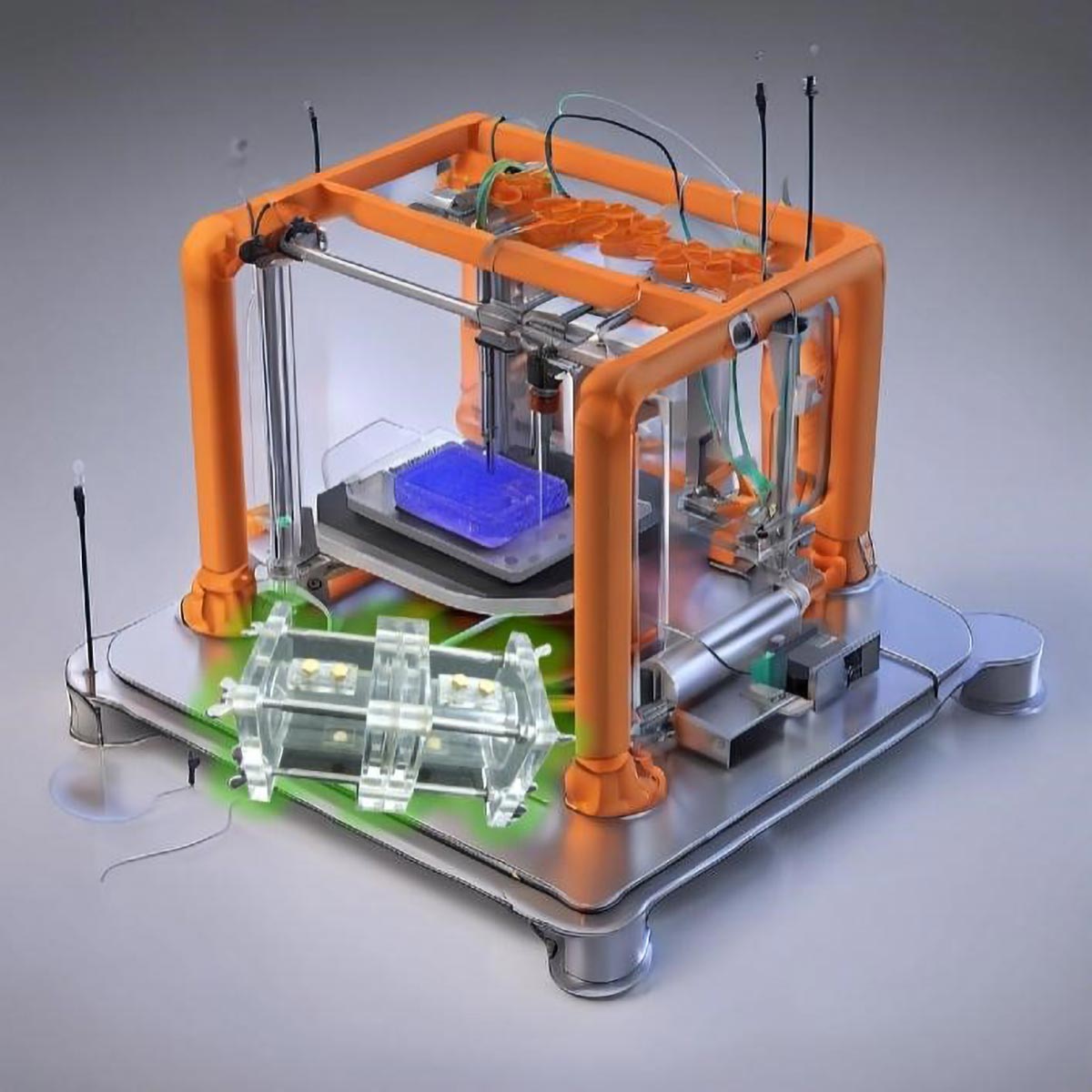

Nestle adopts 3D printing technology as part of a comprehensive strategy to modernise its UK manufacturing operations, establishing standardised processes across multiple production sites over the past year. The global food and beverage giant has implemented additive manufacturing capabilities to produce replacement components and spare parts for its factories, demonstrating a commitment to technological advancement and operational efficiency. This development represents a significant shift in how traditional manufacturing companies approach production challenges and supply chain management.

The company’s 3D printing programme centres around a specialised workshop in York, where a dedicated team of three experts operates the machinery to create components that are subsequently distributed to Nestle’s UK facilities, including sites in Tutbury, Halifax, and York. This centralised approach allows for quality control and standardisation whilst maintaining efficient distribution networks across the company’s manufacturing footprint.

Nestle Adopts 3D Printing Technology

The implementation of 3D printing technology has delivered substantial environmental benefits for Nestle’s UK operations. By producing components in-house rather than sourcing from external suppliers, the company has significantly reduced transportation requirements, leading to lower carbon emissions across its supply chain. This approach aligns with Nestle’s broader sustainability commitments whilst providing practical operational advantages.

The additive manufacturing process itself contributes to waste reduction by depositing materials layer by layer to create precise geometric objects that meet exact specifications. This precision manufacturing approach minimises material waste compared to traditional subtractive manufacturing methods, where excess material is typically removed during production. The ability to create components to exact specifications also reduces the likelihood of part failures and the need for multiple replacement attempts.

Nestle has established an ambitious target to produce over five per cent of its site inventory using 3D printing technology, reflecting the company’s commitment to scaling this manufacturing approach. This goal demonstrates confidence in the technology’s capabilities and indicates plans for significant expansion of additive manufacturing across the organisation’s UK operations.

Industry Collaboration and Knowledge Sharing

Last month, Nestle strengthened its 3D printing capabilities through a collaborative workshop with Markforged, a leading industrial 3D printing technology company, hosted at the York campus. The event brought together industry leaders, engineers, and digital transformation teams to explore scalable implementation strategies for 3D printing in high-volume production environments. This collaborative approach reflects Nestle’s commitment to learning from industry experts and sharing best practices across the manufacturing sector.

“Nestlé has advanced its use of additive manufacturing in production line maintenance by creating a clear, standardized process to evaluate and scale its impact. It’s been great to support their team along the way and see how they laid the foundation for Nestlé’s broader adoption.”

– Alan Yu, Senior Application Engineer at Markforged

The workshop featured hands-on demonstrations and detailed discussions about manufacturing best practices, providing attendees with practical insights into additive manufacturing implementation. Such knowledge-sharing initiatives are crucial for advancing the adoption of 3D printing technology across traditional manufacturing industries, where companies can benefit from shared experiences and proven methodologies.

“As we continue to embrace 3D printing technology, we are not only enhancing our operational efficiency but also paving the way for sustainable manufacturing practices that will define the future of our industry.”

– Simon Billington, Head of Technical & Production at Nestlé UK and Ireland

Looking towards the future, Nestle has outlined plans to expand its 3D printing capabilities to include food-safe components, representing a significant evolution in the application of additive manufacturing within food production environments. The company’s roadmap for the next two to five years focuses on enhancing autonomy in 3D printing operations, ensuring that individual sites can independently meet component demands whilst maintaining high standards of quality and efficiency. This decentralised approach could further reduce lead times and improve operational flexibility across Nestle’s UK manufacturing network.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.