Honeywell, an MNC operating in aerospace and building technologies, performance materials & technologies, and safety & productivity solutions and SLM Solutions, German manufacturer of metal 3D printers, achieve an important success in their development collaboration for the qualification of 3D printed aluminium alloy parts printed with high layer thicknesses.

Newly developed parameter sets for 3D printed aluminium alloy F357, a new beryllium free version of AlSi7Mg0,6 (A357), lead to considerably improved material properties compared to parts produced through die-casting.

The work between Honeywell and SLM Solutions, announced in 2019, aims to reduce manufacturing times and costs to produce 3D printed aircraft components that meet the high requirements of the aerospace industry.

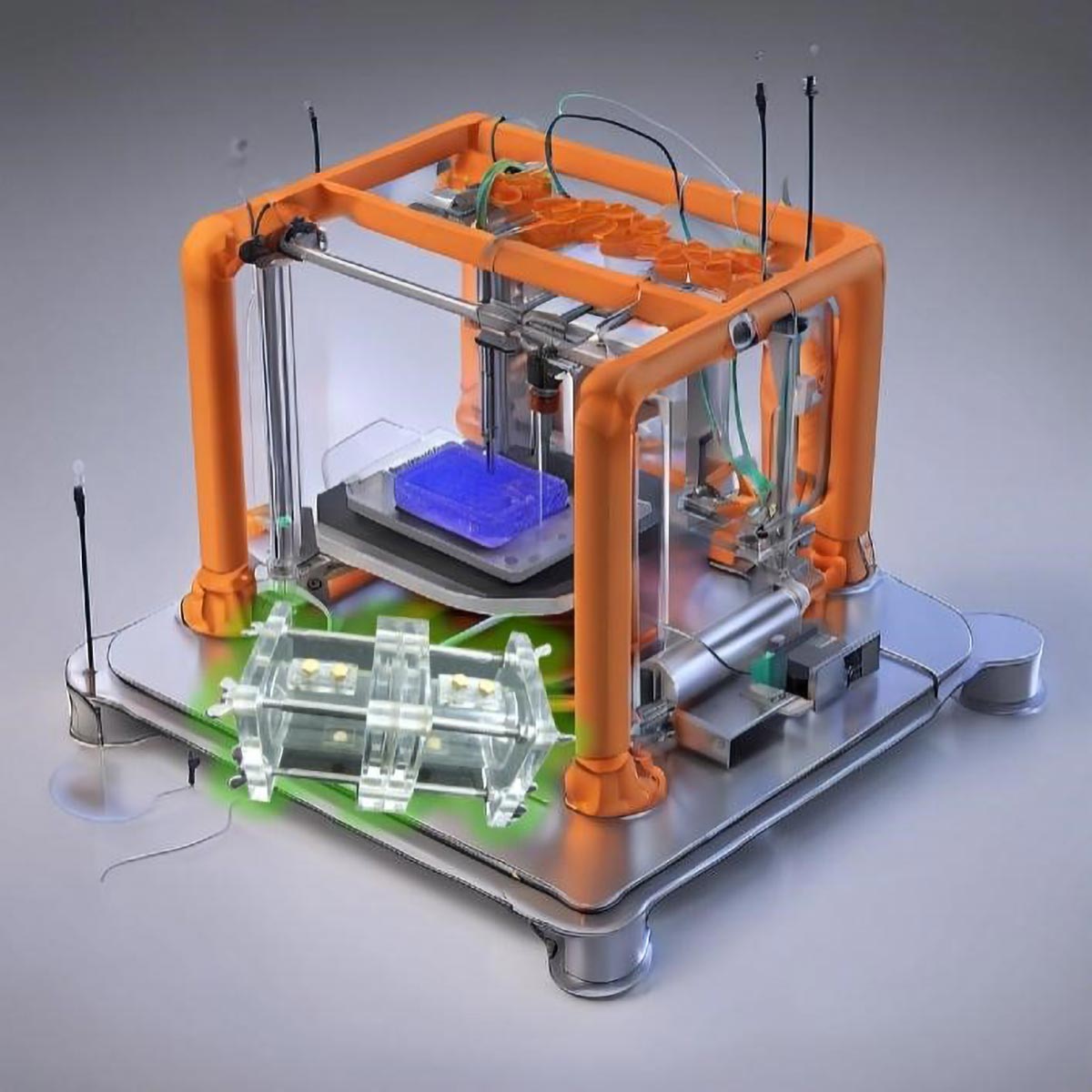

As part of the collaboration that kicked off in 2019, Honeywell began qualification efforts for aluminium builds using an increased layer thickness of 60 and 90 µm on their quad-laser SLM®500 Selective Laser Melting Machine. SLM Solutions provided generic aluminium parameter sets for Honeywell to complete material qualification to achieve optimal material properties. The development of these new parameter sets for 3D printed aluminium alloy F357 using a layer thickness of 60 µm and 700 W lasers has now reached an important milestone. Material properties have significantly increased in comparison to conventional die-cast parts and are now exceeding overall acknowledged metallic properties for aerospace.

3D printed aluminium alloy F357 is not only lightweight but offers a significantly better corrosion resistance and desired mechanical properties, such as high-strength across a wide temperature range in comparison to conventional aluminium alloys. It has a great weldability and excellent suitability for post-processing, like mechanical machining or electrochemical such as anodizing. This combination of properties enables F357 to be perfectly suited for thin walled and complex structures in, for example, the aerospace or automotive industry.

Dr. Sören Wiener, Senior Director Technology and Advanced Operations at Honeywell Aerospace, comments on his work with the SLM®500 saying, “In particular, the open architecture system of the SLM® machine provides huge advantages like high flexibility and parameter sets can be customized. With this open access strategy and the great support of SLM Solutions, we step forward to achieving our next goals.”

Benjamin Haas, Product Manager for Materials & Parameters at SLM Solutions explains, “It is a privilege to work together with one of the leading companies in the aerospace world. This way, we can learn a lot from each other leading to perfectly suited, industry proven solutions from which all of our customers can benefit”.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.