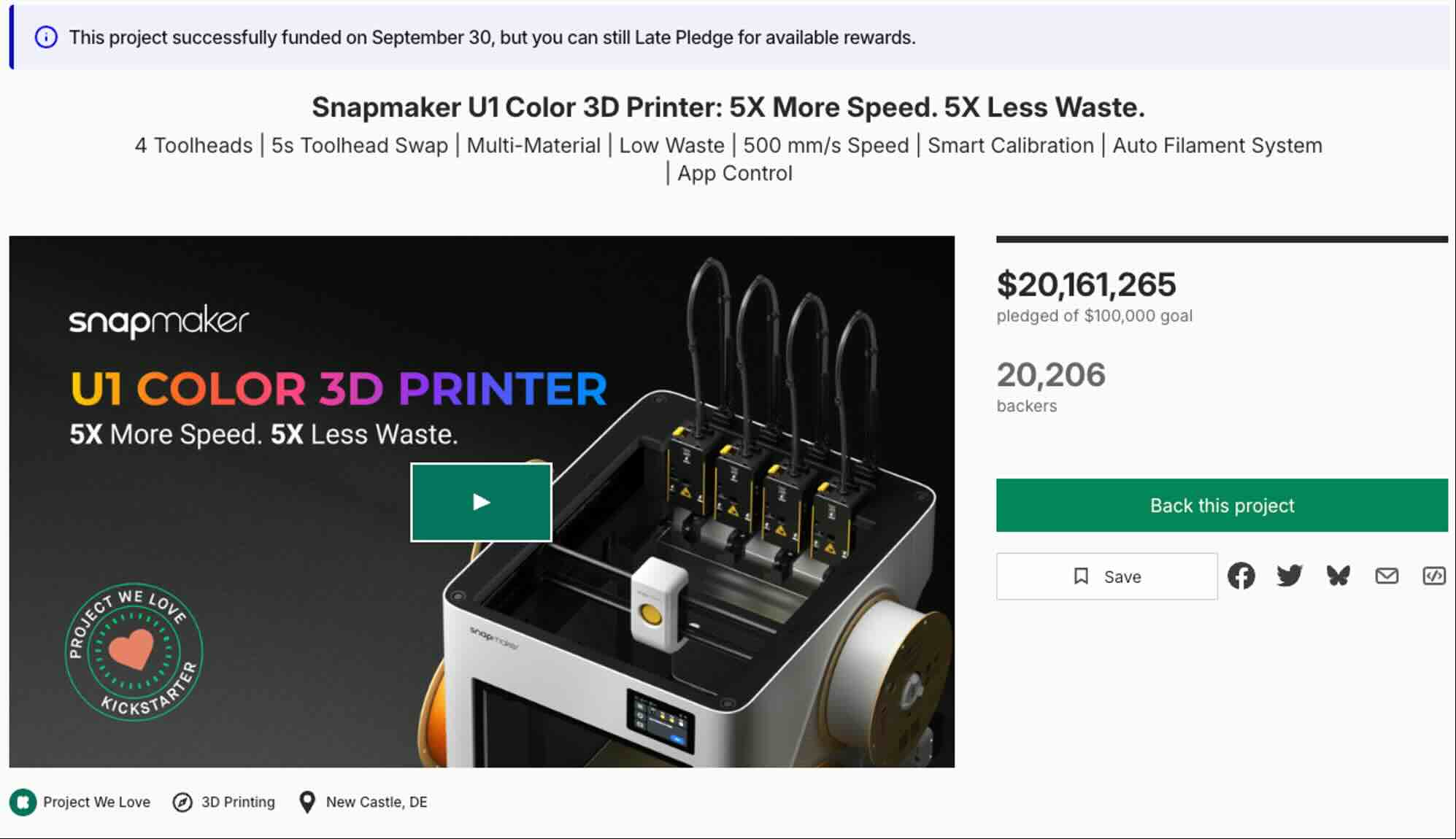

Snapmaker has achieved a historic milestone in crowdfunding for additive manufacturing technology, with the Snapmaker U1 campaign becoming the most funded 3D printer project in Kickstarter history. As of 30th September, the revolutionary four-head tool-changing system has raised $20,161,265 from 20,206 backers worldwide, establishing a new benchmark for community-supported 3D printing innovations.

Makers who missed the initial campaign period can still participate through a late pledge tier priced at $849, providing access to the U1’s groundbreaking performance and versatility.

Community-Driven Success Strategy

Snapmaker’s record-breaking achievement stems from extensive community involvement throughout development. The company implemented a large-scale beta testing programme that provided makers with early access, generating invaluable feedback that shaped the final product. Beta users shared their experiences publicly as the Kickstarter campaign launched, building authentic momentum.

Community engagement extended to prominent maker events across Europe and North America. At Maker Faire Hannover, PrintedHub in Germany, and 3DPrintopia in the United States, potential backers gained hands-on experience with the U1 before pledging. Snapmaker maintained transparent communication through frequent updates, responsive customer service across Discord and Facebook groups, regular livestreams, and behind-the-scenes factory production footage.

Strategic Partnerships and Kickstarter Stretch Goals

The campaign benefited substantially from strategic partnerships with leading maker ecosystem brands. KIRI Engine provides every backer with one month of complimentary mobile 3D scanning access. HueForge unlocks creative colour-mapped lithophane workflows, whilst Polymaker delivers officially supported filament profiles as the first third-party material manufacturer to receive U1 integration.

Upon surpassing the $20 million threshold, Snapmaker activated stretch goals providing every backer with a $10 HueForge coupon (including FlatForge) and a $20 Snapmaker Store coupon, sharing the campaign’s success directly with the community.

Multi-Material Technology in Snapmaker U1

The Snapmaker U1 distinguishes itself through tool-changing architecture featuring four independent print heads equipped with the proprietary SnapSwap system. This technology enables five-second tool changes without wasteful filament purging, delivering both environmental benefits and material cost savings.

The system incorporates CoreXY motion architecture with acceleration up to 20,000 mm/s², achieving print speeds five times faster than conventional systems whilst maintaining precision. This combination results in 80% less waste compared to traditional filament changing systems.

Technical specifications include 300°C hotends capable of processing engineering-grade materials, heated bed for optimal adhesion, integrated camera for remote monitoring, and wireless connectivity. The system operates on Snapmaker Orca, built upon OrcaSlicer and Klipper firmware, providing users with proven software environments.

The U1’s capabilities extend beyond basic colour changes to functional multi-material prints combining different mechanical properties, opening applications in prototyping, engineering validation, and artistic creation previously challenging with single-material systems.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.