Executive Summary

The South Korean defence industry has shown the initiative to adopt advanced additive manufacturing technologies and have demonstrated how it can transform military equipment performance. This conclusion resulted from the partnership between AM Solutions and its military logistics units.

This case study examines the successful redesign of ice cleats for the K2 Black Panther main battle tank, achieving a remarkable 60% weight reduction whilst maintaining full operational capability. The project showcases practical applications of metal 3D printing technology in addressing critical defence sector challenges.

The Challenge

The K2 Black Panther tank operates in extreme winter environments where standard rubber track pads must be replaced with metal ice cleats to provide essential grip on frozen terrain. These components presented several operational challenges:

Heavy Weight: The traditionally used ice cleats weight 10.74 kilograms per unit with each tank requiring around 30-50 units during winter season This also meant that the soldiers responsible for installing and removing the cleats were under severe physical strain during time-sensitive battlefield conditions.

Operational Efficiency: . The cleats add around 322 to 537 extra weight to the tank. This impacts the tank performance and fuel consumption, particularly during extended winter deployments where every kilogram impacts operational range and effectiveness.

Logistics Complexity: Due to its essential nature and its weight, the logistics of these parts are complicated, affecting deployment readiness and maintenance operations.

The Solution

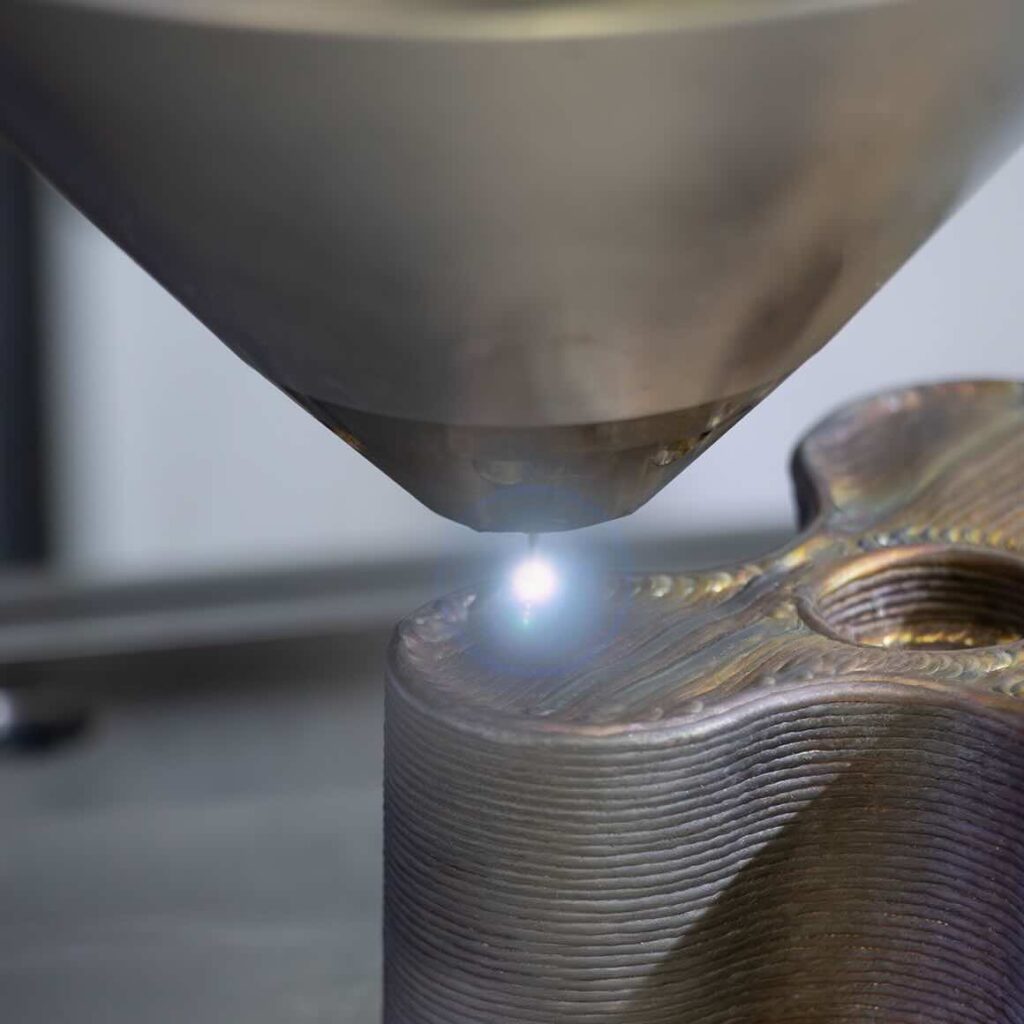

AM Solutions, an official partner specialising in modular additive manufacturing systems for defence applications, leveraged Meltio’s M600 system which uses Laser Wire Directed Energy Deposition (LW-DED) technology to completely reimagine the component design.

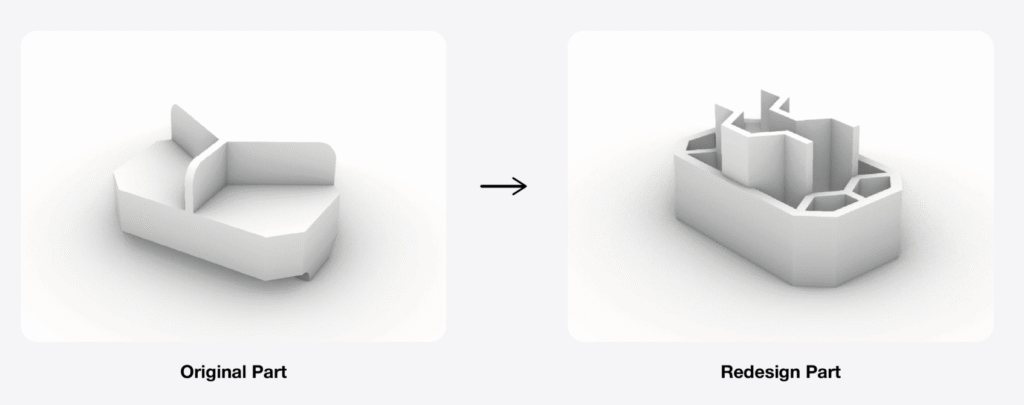

Design Approach

The engineering team implemented a honeycomb structure specifically optimised for additive manufacturing capabilities. This approach enabled:

- Complete structural redesign without compromising mechanical properties

- Elimination of traditional tooling and mould requirements

- Rapid prototyping and design iteration capabilities

- Integration of terrain-specific performance enhancements

Manufacturing Process

The wire-based manufacturing process delivered several technical advantages:

- Material utilisation rates up to 99%

- No post-processing requirements

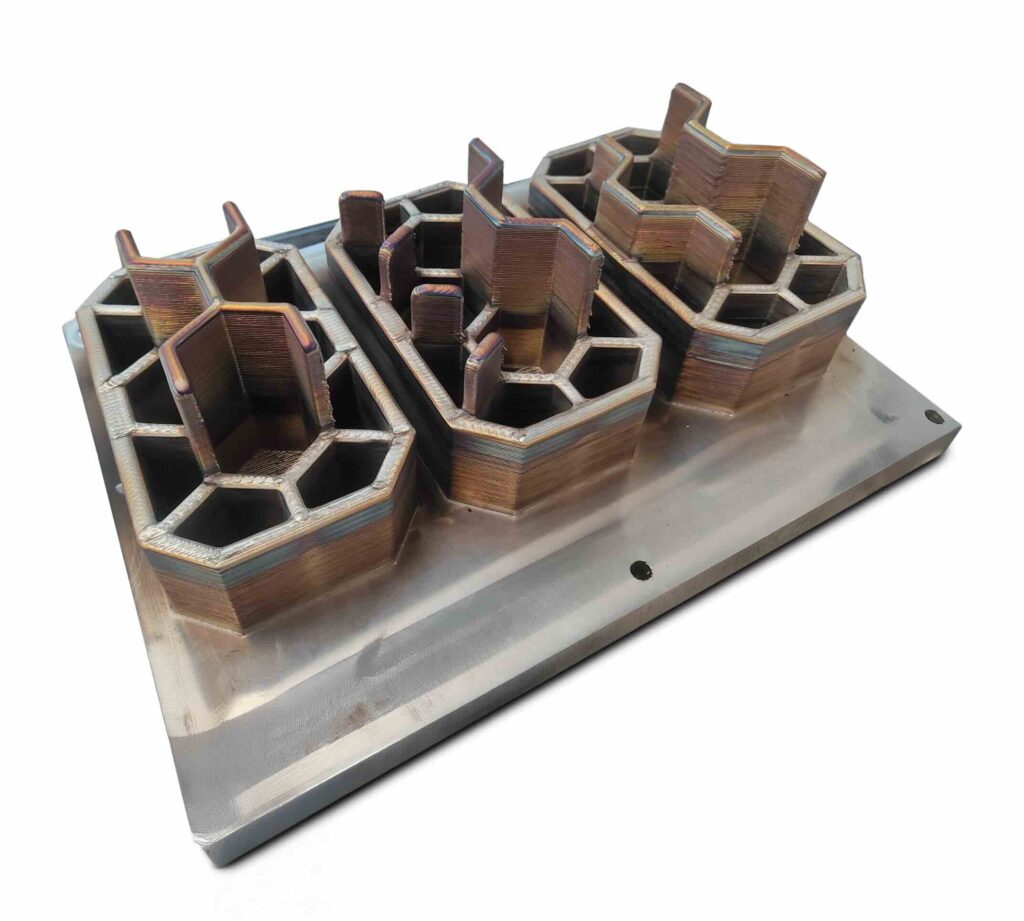

- Capability to produce three components simultaneously per print cycle

- On-demand production supporting real-time logistics

Results and Impact

| Traditional Ice Cleat | Meltio-Printed Cleat | |

| Weight | 10.74 kg | 4.26 kg |

| Material | S45C (Conventional) | SS316L (3D printed) |

| Tooling needed | Yes | No |

| Repair possible | No | Yes (via DED) |

| Fuel efficiency gain | – | +0.64% |

Quantified Outcomes

- Weight Reduction: 60% decrease from 10.74kg to 4.26kg per component

- Fuel Efficiency: 0.64% improvement demonstrated in field trials

- Material Waste: Reduced to less than 1% through wire-based process

- Production Flexibility: Enabled simultaneous multi-component manufacturing

Operational Benefits for South Korean Defence Forces

Soldier Performance: As the 3D printed cleats were only 40% of their earlier weight, they dramatic increased soldier performance by reducing their physical burden during component installation and removal operations, improving readiness and reducing fatigue-related performance degradation.

Tank Efficiency: The efficiency of the tank also improved due to 60% reduction in extra weight. Lighter components meant the fuel efficiency and overall vehicle performance improved during winter operations.

Logistics Optimisation: Since the new cleats can be manufactured on-demand, it reduced inventory requirements and enabled responsive field logistics.

Maintenance Enhancement: The 3D printed cleats can be selectively repaired, rather than replaced thereby increasing their life and saving huge operational costs.

Technology Implementation

Manufacturing System

The project utilised advanced metal 3D printing technology featuring integrated 3-axis probing systems and comprehensive work-holding solutions ideal for defence manufacturing operations.

Material Selection

Stainless Steel 316L wire feedstock provided cost-effective and safer alternatives to powder-based manufacturing approaches whilst maintaining required mechanical properties.

Quality Assurance

Rigorous testing confirmed that redesigned components maintained all mechanical properties required to withstand substantial loads and stresses imposed by tank operations.

Strategic Applications of Advanced Metal 3D Printing

Legacy Component Reconstruction

The technology addresses the common challenge of obsolete parts from older military equipment generations no longer in production. Additive manufacturing enables cost-effective, low-volume reproduction of critical components, extending platform operational life without requiring complete upgrades.

Tactical Field Repair

Mobile manufacturing solutions enable deployment of production capabilities directly to operational environments. This containerised approach provides on-site component production and repair, dramatically improving readiness and responsiveness in tactical situations.

Lessons Learned

Design Innovation: Traditional manufacturing constraints need not limit component performance when advanced additive manufacturing capabilities are properly leveraged.

Integration Success: Careful collaboration between technology providers and end-users ensures solutions address real operational requirements rather than theoretical improvements.

Scalability Potential: Successful implementation in one application area opens opportunities for broader technology deployment across defence infrastructure.

Future Implications

This case study demonstrates the transformative potential of advanced manufacturing in defence applications. It also strengthens the use case of defence applications and also highlights how Meltio is transforming defence sectors across the world.

The combination of substantial weight reduction, improved operational efficiency, and enhanced logistics flexibility provides a framework for broader technology adoption across military platforms.

All the gains achieved in this case are highly important for all defence operations and so it provides valuable guidance for future additive manufacturing implementations in defence sector.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter. Follow us on Google News.