3D printing technology has enabled Northwestern University researchers to overcome a significant limitation in ceramic-based superconductors. Professor David Dunand and collaborators from Fermilab have developed a method to produce single-crystal YBCO superconductors using additive manufacturing techniques, addressing the brittleness issue that has long restricted the potential applications of ceramic-based cuprate superconductors.

The research, detailed in the paper “Additively-manufactured Monocrystalline YBCO Superconductor” published in Nature Communications on February 24, represents a breakthrough that could reduce costs and expand applications for superconductor technology. Dunand worked alongside Dingchang Zhang, a postdoctoral researcher at the University of California, Berkeley, and former student in Dunand’s lab, and Cristian Boffo, PIP-II project manager at Fermilab.

Additively Manufactured Ceramic-based Superconductors

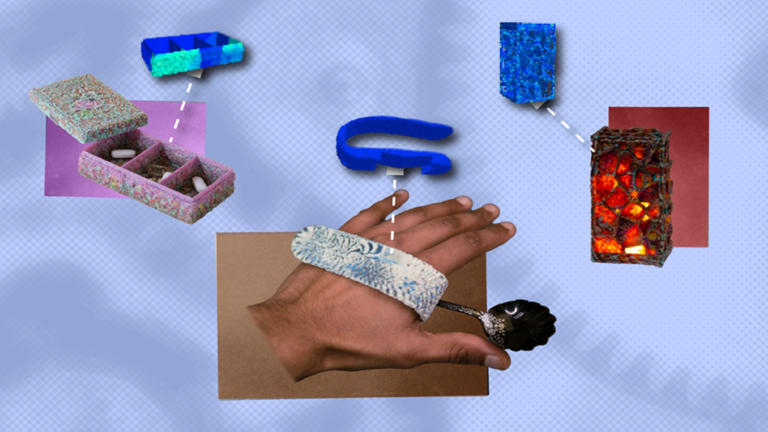

The new manufacturing method overcomes traditional limitations by combining additive manufacturing with a melt growth technique. The process begins with commercially available precursor powder used to prepare ink, which is then loaded into a syringe and extruded to create complex YBCO micro-lattices or other geometries that start as polycrystals.

These 3D-printed structures are subsequently transformed into single crystals through a controlled melt growth method. By placing a single crystal seed on top of the printed parts and carefully controlling the processing conditions, the researchers cause the printed parts to partially melt and transform into single crystals while retaining their original printed shapes.

This technique differs significantly from conventional superconductor production methods, which typically involve mould pressing powders into simple forms followed by sintering. The traditional approach limits the geometric complexity of the final product and retains grain boundaries that reduce performance.

“People have made single crystals in a block of material, and we’ve shown we can use this same technique with 3D printing,” explained Zhang. “Through a controlled processing window, these 3D-printed parts partially melt and transform into single crystals, retaining their original 3D-printed shape.”

Superior Performance for Advanced Applications

A critical achievement of this research is the elimination of grain boundaries—small defects in crystal structures that diminish electrical and thermal conductivity. By removing these boundaries, the team produced superconductors capable of carrying greater electrical current, resulting in more powerful materials.

“The single-crystal object can carry a greater amount of electrical current, making it able to provide more power, thus making magnets immensely stronger. This provides more energy for particle accelerators, such as FermiLab. The faster particles may in fact unlock new discoveries for physicists.”

– David Dunand, professor of materials science and engineering at the McCormick School of Engineering

Ceramic-based cuprates like YBCO are particularly valuable as high-temperature superconductors because they can operate with liquid nitrogen cooling, making them considerably less expensive and easier to work with than low-temperature metal superconductors. The ability to form these materials into complex, optimised shapes opens new possibilities for energy-efficient designs.

The technique’s impact extends beyond academic research. “At Fermilab, we are developing the next-generation superconducting magnets that will drive scientific experiments for decades to come,” noted Boffo. “The technology created through this collaboration will enable designs that were previously unimaginable, thereby enhancing our potential for advancement.”

Future Research Directions

The research team views this work as just the beginning of expanded possibilities for superconductor technology. They plan to apply their method to other ceramic superconductor materials that may offer even higher performance characteristics.

“We did this research with YBCO, the most common superconductor, but there are many other compounds with even higher performance temperatures than can be processed by our method,” Dunand explained. “The possible applications for this are very exciting.”

Superconductors already play vital roles in numerous fields, from medical imaging in MRIs to energy-efficient transportation in magnetic levitation trains. With the ability to create stronger, more complex superconducting structures, this research may lead to cost reductions and performance improvements across these applications. The team’s breakthrough addresses a fundamental challenge in materials science: how to maintain the beneficial properties of ceramic materials while overcoming their inherent brittleness. By enabling the creation of complex, single-crystal structures, the researchers have opened new avenues for superconductor application and development.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Tech News page for more updates on 3D Printing Technology News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.