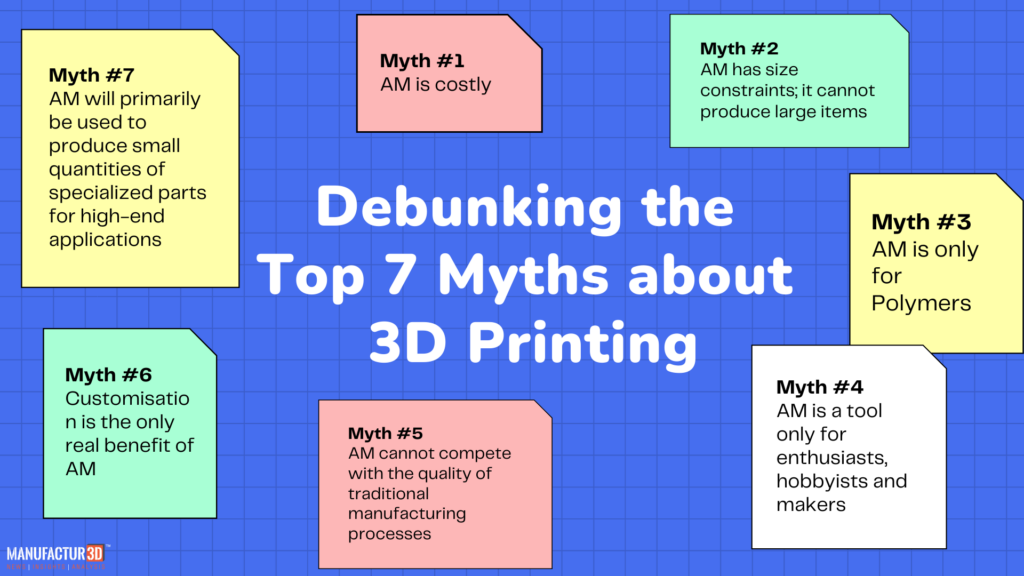

3D printing is becoming a common place on factory floors as well as in offices. The technology’s wide range of uses and applications make it an ideal future technology. However, there are numerous myths about 3D printing. From the myth that additive manufacturing (AM) is expensive to the myth that it is a sub-standard technology. The myths are many, but the fact remains that 3D printing is the technology of our future.

This article aims to debunk the top 7 myths about 3D printing by providing practical and real-world examples.

Top 7 Myths About 3D Printing

Myth #1: AM is costly

The capital costs of implementing additive manufacturing are currently high, but they have decreased significantly over the last decade and will continue to do so in the future. In terms of production, AM is actually less expensive than traditional manufacturing processes because it eliminates the need for tooling. In cases where tooling is required, 3D printed tools can be produced quickly, eliminating the time-consuming traditional tool manufacturing process. 3D printed tools are also distinct, effective, and more efficient than traditional ones.

Moreover, there are many products that have been completely transformed by 3D printing and one of them is prosthetics. Traditional prosthetics are heavy, bulky, and cost a fortune and sue to which they cannot be replaced frequently. Especially in the case of kids who are continually growing. 3D printed prosthetics solves all these issues while bringing the cost down.

Real-world examples such as like 3D printed tooling, 3D printed prosthetics and Audi explores 3D printed tooling applications will help you debunk this myth.

Myth #2: AM has size constraints; it cannot produce large items

This is also one of the popular myths in 3D printing that AM can only produce small parts. Though it may have been true in the early days of technology, it is most emphatically not true today.

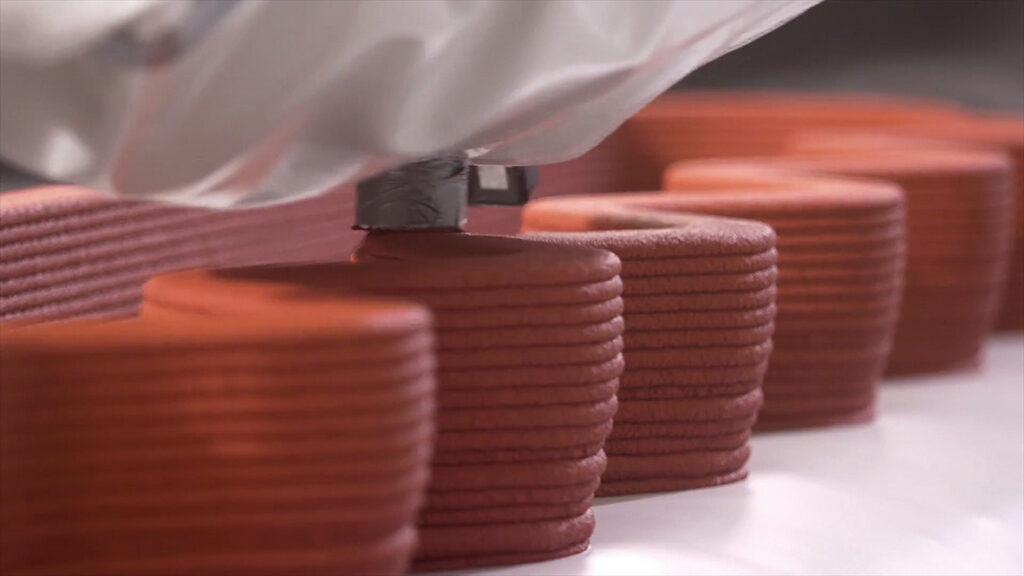

3D printers are now used to create massive ship parts, aircraft wings, bridges and buildings. Even a smaller desktop printer with a conveyor belt is capable of producing parts much larger than its print bed. As a result, size is no longer a constraint.

Real-world examples like 3D printed boat, 3D printed steel footbridge, and largest 3D printed office will help you bust this myth.

Myth #3: AM is only for Polymers

Additive manufacturing is a technology that can cross industry boundaries and use the most diverse range of materials of any technology group. This means that AM can work with polymers (thermoplastic and thermosetting), metals (Stainless Steels, Aluminium, Copper, Nickel, Inconel, Titanium, Gold, Silver, and so on), composites (polymers reinforced with fibers), ceramics, wood, food, stem cells, and so on.

Check the materials used in 3D printing article to know more about the AM materials range.

Real-world examples like metal 3D printing, concrete 3D printing, and wood 3D printing will help you bust this myth.

Myth #4: AM is a tool only for enthusiasts, hobbyists and makers

The fact that the majority of the world’s leading conglomerates are investing heavily in 3D printing and also charting strategies to incorporate the technology into their manufacturing workflow is enough to dispel this myth. Aerospace, automotive, medical, and defence companies, among others, are at the cutting edge of technology.

Many companies have already standardised AM parts for mission-critical components.

Real-world examples like 3D printed rocket engine, replacement parts for military, and 3D printing for spinal implants will help you debunk this myth.

Myth #5: AM cannot compete with the quality of traditional manufacturing processes

This myth can also be debunked by looking at the examples in Myth #3, which show that 3D printed products are used in mission-critical applications requiring high precision, accuracy, and quality. Aviation and aerospace, medical and healthcare, defence, motor racing, and other industries have high product qualification standards, and AM is already being used in these industries.

Today’s additive manufacturing technologies are rapidly improving to the point where they can now provide higher quality at a lower cost for a wide range of important product categories.

Real-world example like metal 3D printed part on flight will help you bust this myth.

Myth #6: Customisation is the only real benefit of AM

Customization is without a doubt one of the most significant advantages of AM. It is unprecedented and gives it a competitive advantage over traditional manufacturing processes. Aside from customization, many other advantages also make AM the technology of choice for the future. Other significant advantages include reduced material waste, lighter product weight, easier assembly, lower capital costs, a smaller manufacturing footprint, and more.

Real-world example like data-driven 3D printed shoe, 90% wastage reduction and 10% reduced weight of part, and $10K savings per month will help you bust this myth.

Myth #7: AM will primarily be used to produce small quantities of specialized parts for high-end applications

This is also one of the most common myths about 3D printing that needs to be debunked. AM has grown tremendously in the last decade, and we can see the results in how quickly it is being adopted for mass production. New technologies have also emerged, allowing for the mass production of parts on a 3D printer.

It is important to note that, while 3D printing cannot currently match the quantities produced by technologies such as injection molding, the technology’s rapid advancement suggests that it will not be long before 3D printing becomes a mass production technology.

Another important point to consider is that, whereas traditional technologies rely on economies of scale, 3D printing is better suited to economies of scope. As a result, in the future, the technology may not even need to be ‘mass-production’ technology. Technology will be equally effective while delivering economies of scope while clubbing strategies such as bridge manufacturing, distributed manufacturing, and on-demand capabilities with virtual warehouses.

Real-world examples like mass production in AM, tripling manufacturing capacity, serial production for vehicles, and mass production for defence will help you bust this myth.

Summary

| Myths | Fact |

| AM is costly | The capital costs of implementing AM are currently high, but they show a decreasing trend over the last decade and will continue to do so in the future. AM actually saves money on production because it eliminates the need for tooling. |

| AM is only for Polymers | AM uses a wide variety of materials, including metals (SS, Cu, Nickel, Titanium, Gold, and so on), concrete, ceramic, wood, stem cells, food, and so on. |

| AM has size constraints; it cannot produce large items | AM is now used to construct massive ship parts, aircraft wings, and even buildings using concrete 3D printing. The size is not a constraint. |

| AM is a tool only for enthusiasts, hobbyists and makers | The majority of the world’s leading conglomerates are heavily investing in and charting paths to incorporate the technology for all of their future product manufacturing. |

| AM cannot compete with the quality of traditional manufacturing processes | AM technologies are rapidly improving to the point where they can now provide higher quality at a lower cost for a wide range of important product categories. |

| Customisation is the only real benefit of AM | Customisations is one big benefit of AM. However, there are numerous other advantages as well, such as less material waste, lighter product weight, easier assembly, lower capital costs, a smaller manufacturing footprint, and so on. |

| AM will primarily be used to produce small quantities of specialized parts for high-end applications | AM now provides such significant quality, efficiency, and cost benefits that it is increasingly being used for mass production of standardized products. |

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.