In the evolving landscape of construction, sustainable practices are becoming increasingly essential. By harnessing the potential of additive manufacturing and fabric structures, the industry can move towards more eco-friendly building solutions, reducing waste and enhancing efficiency.

The construction industry faces significant pressure to adopt sustainable practices due to growing environmental concerns. Implementing eco-friendly methods reduces resource consumption and minimizes waste production, addressing critical issues in modern building projects. Additive manufacturing and engineered fabric building offer promising solutions in this regard. By integrating these technologies, the construction sector can significantly reduce its environmental footprint while improving project efficiency.

Role of Additive Manufacturing in Construction

Additive manufacturing, commonly known as 3D printing, is transforming material usage in construction by minimizing waste. This technique involves creating structures layer by layer, ensuring precision and efficiency in material utilization. With this approach, construction projects can achieve higher levels of customization without excess material loss. By reducing the traditional wastage associated with cutting and molding materials, 3D printing becomes a pivotal technology in sustainable construction.

Beyond material conservation, 3D printing enhances the creation of complex architectural components that would be challenging or impossible with conventional methods. This precision saves resources and accelerates project timelines by eliminating the need for multiple adjustments during assembly. Consequently, additive manufacturing aligns seamlessly with the goals of reducing environmental impact while maintaining high standards of construction quality.

The technology supports innovation in design and functionality. The ability to print on demand means components can be tailored specifically to project requirements, enhancing both structural integrity and aesthetic appeal. This adaptability is particularly beneficial in urban settings where space constraints necessitate compact yet functional designs. By fostering creativity alongside sustainability, additive manufacturing sets a new benchmark for modern construction practices.

Advantages of Fabric Structures

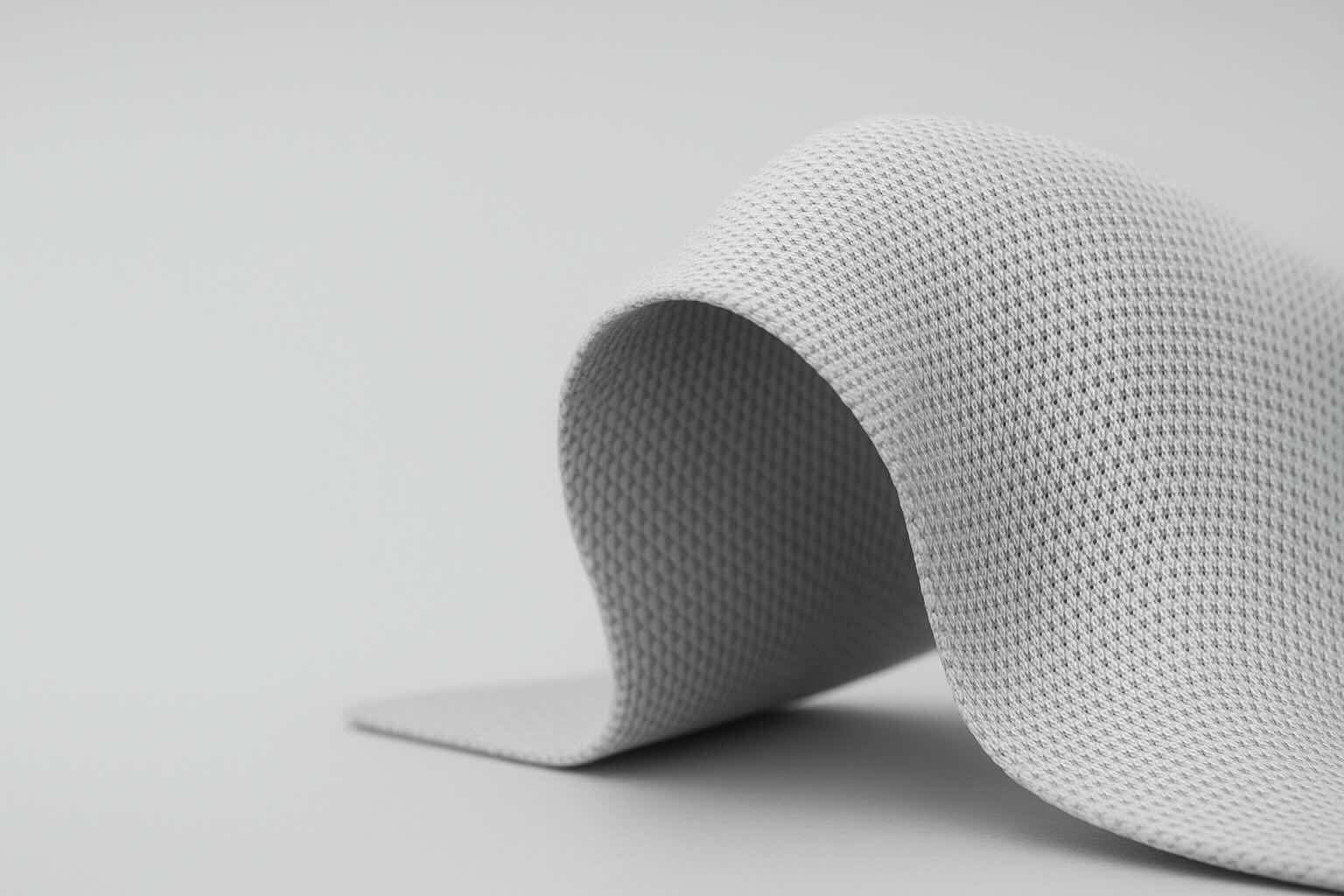

Fabric structures offer a unique blend of durability and versatility, making them ideal for sustainable construction projects. These structures are lightweight yet resilient, capable of withstanding various environmental conditions while requiring fewer resources than traditional buildings. The use of tensile fabrics reduces overall material consumption, contributing to lower carbon footprints during both production and transportation phases.

Another advantage of fabric buildings lies in their energy efficiency. The materials used often possess insulating properties that help regulate interior temperatures, reducing the reliance on artificial heating and cooling systems. This characteristic lowers operational energy costs and minimizes emissions related to energy consumption. As such, fabric structures represent a forward-thinking approach to sustainable building design.

In addition to their environmental benefits, fabric buildings are also known for their adaptability to different project needs. They can be easily dismantled and relocated or reconfigured to suit evolving requirements, offering long-term flexibility that is often absent in permanent constructions. This makes them particularly appealing for temporary installations or areas prone to rapid change, further underscoring their role in sustainable development strategies.

Combining Additive Manufacturing and Fabric Structures

The combination of additive manufacturing with fabric structures amplifies the sustainability potential within the construction industry. By integrating 3D-printed components into fabric frameworks, builders can create innovative structures that leverage the strengths of both technologies. For example, customized connectors or support elements printed on-demand enhance the functionality and stability of tensile buildings.

This integration allows for seamless incorporation of complex designs that optimize space utilization and structural efficiency. Through strategic use of materials and advanced design capabilities offered by 3D printing, these hybrid constructions deliver enhanced performance without compromising ecological goals. The flexibility inherent in both technologies ensures that each project is tailored precisely to its context.

These combined methodologies enable new forms of architectural expression by facilitating intricate geometries not feasible with conventional methods alone. This opens up opportunities for unique aesthetic experiences while adhering to sustainable principles. As industries continue exploring these synergies, the potential for transformative impacts on construction practices becomes increasingly evident.

Environmental Impact

The environmental advantages of adopting additive manufacturing and fabric structures are substantial when considering waste reduction in construction activities. Both approaches significantly decrease material wastage through precise resource allocation and innovative reuse strategies within project cycles.

By minimizing unnecessary resource extraction and processing associated with traditional building techniques, these technologies contribute positively towards conserving natural ecosystems worldwide. Additionally, they align closely with global sustainability objectives aimed at mitigating climate change effects through reduced greenhouse gas emissions.

Embracing these advancements fosters a more responsible approach towards land development across diverse sectors and encourages stakeholders to prioritize ecological considerations alongside economic gains as part of holistic planning processes moving forward.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, follow us on Facebook, LinkedIn and Twitter.