Whether you are someone who enjoys 3D printing as a hobby or want to make a career out of it, you may be constantly annoyed by the quality of the prints that you are getting. Any print that initially looked just about perfect in your slicer ends up being stringy, brittle, or just… off. You try out every possible thing from double-checking your temperatures, re-levelling your bed, swapping nozzles, trying out different filaments to even re-slicing the file, but all in vain. But did you know that there is a silent killer in 3D printing which you may not be aware of – Moisture!

Humidity is something most people usually do not even think about when 3D printing but it has a major impact on prints. Hence, we are going to further discuss how moisture can impact prints adversely and how to save yourself from this frustrating yet easily solvable problem.

Moisture – The Silent Killer in 3D Printing

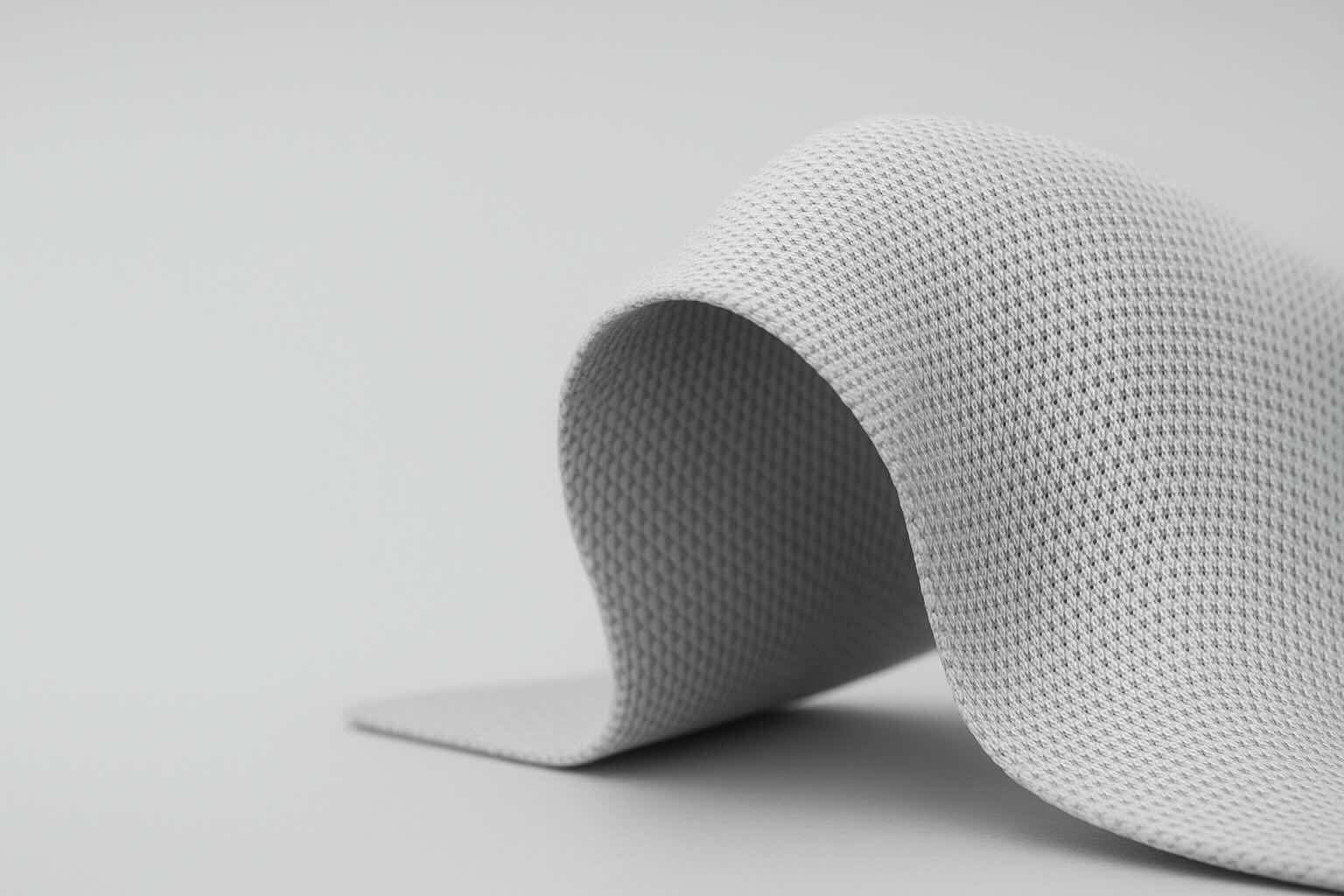

Usually, all filaments used in 3D printing from Nylon and Polycarbonate to PLA and PETG are hygroscopic. This means that they absorb moisture from the air. And moisture is pretty much present everywhere! So, even if you feel like your house or workspace is not particularly humid, there is enough moisture there to degrade the performance of your otherwise perfect filaments.

How Moisture Affects Your Filament?

When the filament takes in moisture and goes through the hot nozzle, the water inside turns into steam. This steam creates pressure in the melted plastic, which leads to small bubbles, popping sounds, and uneven flow. All of this can cause problems like:

- Thin strings and blobs where the plastic doesn’t come out clean

- Weak layer bonding, making the print easy to break

- Uneven lines and rough surfaces on the model

- Cracks or parts that snap easily

- Warping or shapes that come out the wrong size

Even a little moisture can mess up the whole print, so it’s important to keep your filament dry before you start.

Moisture Costs You Time and Money

3D printing has grown way beyond just being a fun weekend project. These days, it’s a big part of how many people run their businesses, test new ideas, or even build products. And when a print doesn’t come out right? It’s not just annoying — it can cost you time, money, and materials.

A poor quality print means wasted filament, several hours of hard work lost and sometimes even hardware wear if clogs and retractions start stacking up. This impacts one drastically especially while doing a long print that needs to be repeated when it is not perfect.

Thus, it is extremely important for 3D printer owners to prevent moisture damage and save up on time and money.

Drying vs. Storing: Why Both Matter

Many 3D printers think that storing the filament in sealed boxes is enough but unfortunately, they are wrong. Dry boxes, vacuum bags, and silica packs can help slow down moisture from getting into your filament, but once the damage is done, they can’t fix it. That’s where filament dryers really shine — they help bring your filament back to life and ready to print again so none of it goes to waste.

Filament dryers use steady heat to remove moisture out from deep inside the filament. They are perfect for drying tricky materials like Nylon, PETG, TPU, or even regular PLA that’s been left out for a while and give you a chance to use them.

How To Choose A Filament Dryer?

Filament Dryers are an up and coming product whose use is being recommended by many professional 3D printers because of the quality of print you get after using it. But, there are quite a few options available in the market that can confuse buyers. So, here are some features to look out for in a filament dryer before purchasing it.

- Ability to store filaments after drying- After spending time and electricity on drying the filament, you definitely do not want to leave it out in the air to absorb more moisture. Thus, try looking for a filament dryer such as the Chitu Systems FilaPartner E1 which has the ability to store the spools after drying.

- Multiple chambers- Try to get a filament dryer that has more than one chamber so that it could dry multiple spools at once. What would make these multiple chambers even more ideal is if you could set a different temperature for each chamber. This would help make your investment cost and time efficient.

- Built-in humidity monitoring- It is a great option to have the ability to see your filament’s condition in real time. With clear readouts, you’ll always know what’s going on — no more guessing if your spools are “good enough” to use.

- Continuous printing mode- There are filament dryers such as the FilaPartner E1 that allow you to print directly from the dryer. This way your filament remains protected throughout the print and you do not need to worry about the filament absorbing even a little moisture at all even if the print is extremely time consuming.

The Ideal Companion For Serious Printers

You might not see moisture but it is the silent killer in 3D printing. It can weaken your prints, waste hours of your time, and make even the best printer setup seem like it’s not working right. The good news? It’s one of the easiest issues to fix, as long as you treat it like a real part of your process.

If you’re aiming for consistent, high-quality prints every time, drying your filament isn’t just a backup plan, it should be part of your regular routine. And if you’re after a reliable solution that actually works in everyday setups, the Chitu Systems FilaPartner E1 is ready to help.

After all, in the world of 3D printing, success is not just about how good your printer is but also about how great your filament is.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, follow us on Facebook, LinkedIn and Twitter.