When I first stepped into the world of 3D printing back in 2016, I found myself drowning in a sea of unfamiliar terms—slicer settings that made no sense, material names that sounded like chemistry exam questions, and troubleshooting advice that might as well have been in another language. I had to rely on existing 3D printing glossary articles and though they were good, I felt it should be more comprehensive. And so I wrote and published this in 2018. Since then I have been updating it every year.

Here at Manufactur3D, we’ve compiled this extensive A-to-Z guide to demystify the technical jargon that often creates barriers for newcomers and even occasionally confuses veterans. This glossary isn’t just a collection of definitions—it’s built from real questions our team has encountered over the course of our existence. Whether you’re a student working on your first project, an engineer exploring additive manufacturing, or a hobbyist setting up your first printer at home, consider this your trusty translator for the language of 3D printing.

For 2025, we’ve completely updated this glossary with the latest terminology, technologies, and trends that have transformed the industry in recent years. From high-speed printing innovations to advanced firmware features and even artificial intelligence, this guide covers everything you need to navigate today’s 3D printing landscape.

3D Printing Glossary

3D Model

A 3D Model is the three dimensional design of the object in a soft format built in a CAD software like Tinkercad, Freecad, etc. (for basic modelling), Solidworks, CATIA, Siemens NX, etc. (for complex industrial modelling).

3D Printer

A machine which builds a solid object by successively adding layers on top of the previous layer by transforming the 3D CAD model into a physical three dimensional object. A 3D printer is capable of building complex geometries previously not possible.

3D Printing

It is the process of adding material in a layer by layer fashion to form a solid object. The process is called printing as it is similar to 2D inkjet printers apart from the fact that 3D printing occurs in three dimensions.

3D printing technology consists of a set of technologies operating on a similar principle of adding material in successive layers. As per ASTM, there are seven broad categories of 3D printing technologies like Vat Photopolymerization, Material Jetting, Binder Jetting, Powder Bed Fusion, Material Extrusion, Directed Energy Deposition, and Sheet Lamination. Although new 3D printing technologies are emerging that do not exactly fit into these seven categories.

3D Scan

A technology which captures digital data of the object. It is scanned via a device without any contact with the actual object. 3D Scans in combination with 3D printing play a crucial role in reverse engineering.

3D Systems

3D Systems is one of the largest 3D printing companies in the world. It was also the first ever 3D printing company to be established as the pioneering manufacturer of Stereolithography (SLA) 3D printers.

A

Acetone

Acetone is a chemical solvent used for two different functions in 3D printing (only in FFF 3D Printing). Firstly, acetone vapour is used to dissolve the surface of the print. This is also called as ‘Acetone Bath’. A small exposure to vapour can help smoothening the print layers on the part.

Secondly, since ABS is prone to warping, it is recommended that the print bed be heated. In addition to this, a few small pieces of ABS material are mixed with acetone to form a sludge. This sludge is popularly called as ‘ABS Juice’. This sludge is sticky and is spread on the print bed and thus holds the print thereby preventing the ABS part from warping while printing.

Adaptive Layer Height

Adaptive layer height is a slicer feature that automatically varies the thickness of each printed layer based on the model geometry. Flatter areas use thicker layers for faster printing, while detailed or curved sections use thinner layers for better quality. This technology, now standard in slicers like PrusaSlicer, Cura, and Bambu Studio, can significantly reduce print times while maintaining quality where it matters.

Adrian Bowyer

This is one of the most famous names in the 3D printing industry and so we cannot miss adding this person in our 3D printing glossary. Adrian Bowyer is a British engineer and mathematician who founded the RepRap project in 2005. As the creator of the first self-replicating 3D printer, Bowyer’s work has been instrumental in democratizing 3D printing technology. His decision to release RepRap as open-source hardware accelerated innovation and dramatically reduced the cost of desktop 3D printers, making the technology accessible to hobbyists, schools, and small businesses worldwide.

AI Build

AI Build is a company that specializes in building AI-powered 3D printing software. It shows the growing influence of AI on 3D printing and shows one example of how AI is being implemented to simplify the workflows

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene or ABS is one of the most commonly used thermoplastic material for 3D printing in an FFF (Fused Filament Fabrication) type of printer. It provides good strength and improved ductility than PLA and so it is preferred over PLA for rapid prototyping of end-use applications. However, ABS is prone to warping.

ABS requires careful printing conditions including an extruder temperature around 220°C, a heated chamber (around 45°C), bed temperature at 110°C, and proper bed adhesion techniques. The material produces fumes during printing, necessitating good ventilation.

Additive Manufacturing

Additive manufacturing is the technical name of 3D printing. Both these terms can be used interchangeably. 3D printing is just more popular and some experts may use one name over the other to distinguish consumer level 3D printing with industrial additive manufacturing.

As the name suggests, any product is manufactured by adding material. The material is added in the form of layers deposited in successive layers to build the complete product. So, Additive Manufacturing is the technology that builds 3D objects by successively adding layer of materials (plastic, metal, ceramic, bio-ink, concrete, etc.) one over the other in perfect geometry to ultimately create the solid object. Read our article on basics of additive manufacturing to know more about this technology.

ASTM

ASTM (American Society for Testing and Materials) International is a globally recognized standards organization that develops and publishes technical standards for a wide range of materials, products, systems, and services, including additive manufacturing. ASTM Committee F42 on Additive Manufacturing Technologies, established in 2009, develops standards specifically for 3D printing. These standards cover terminology, test methods, processes, materials, design, and data exchange, helping to ensure consistency, quality, and safety across the industry. The ASTM F2792 standard provides the official classification system for additive manufacturing processes.

Auto Bed Levelling (ABL)

Auto Bed Levelling refers to systems that automatically measure the height of multiple points across a print bed to create a topographical mesh of the surface. The printer then compensates for any irregularities during printing by adjusting the Z-height in real-time. Popular ABL systems include BLTouch, CRTouch, inductive sensors, and strain gauge sensors.

B

Bambu Lab

Bambu Lab is a Chinese 3D printer manufacturer founded in 2021 that quickly disrupted the market with its high-speed, feature-rich printers. Their X1 series and P1 series printers introduced consumer-level machines capable of speeds up to 500mm/s with acceleration up to 20,000mm/s², along with features like multi-material printing, lidar-based calibration, and AI print monitoring. Their entrance into the market has forced established manufacturers to accelerate their innovation timelines.

Bed Adhesion

Bed adhesion refers to how well the first layer of your print sticks to the build platform. Poor bed adhesion is one of the most common reasons for print failures. Ensuring proper bed adhesion requires thoroughly cleaning the bed with isopropyl alcohol before each print, proper bed levelling, and adjusting the nozzle height to get a slightly squished first layer. For stubborn materials, a thin layer of glue stick or specialized adhesives can improve adhesion.

Belt Printer

A belt printer is a 3D printer that uses a moving conveyor belt as its build surface instead of a traditional static print bed. This design allows for continuous or “infinite” printing in one dimension and enables automatic part removal as completed prints simply roll off the end of the belt.

Notable examples include the Creality CR-30, Powerbelt3D, and Blackbelt 3D printers. Belt printers excel at batch production of similar parts and unusually long objects, though the 45-degree print orientation requires specific design considerations.

Binder Jetting

It is a 3D printing technology used to print large and complex parts in industrial-grade materials. It uses a binding agent and material in powdered form. The liquid binder acts as a binding agent to the powdered layers of the material. The print head moves horizontally along the X-Y direction depositing the binder while the bed which holds the powdered material moves in Z-direction. After successive layers, the object is completely printed and is supported by the surrounding powder. The material can be metal, sand and ceramic. Read our article how binder Jetting works to know the working of this technology.

Bioprinting

Bioprinting is three-dimensional printing of artificial tissues in an additive layer-by-layer process. The printing material is developed from existing cellular building blocks also called as bio-ink. This bio-ink is then printed in a layer-by-layer process in a bio-inert hydrogel which acts as a support and as a filler for void spaces to accurately mimic the feature of tissues.

Bowden Extruder

A Bowden extruder system is a type of extrusion setup where the extruder motor is mounted to the printer’s frame rather than directly on the print head. It uses a PTFE tube to guide the filament from the extruder to the hot end. This configuration reduces the moving mass of the print head, allowing for faster print speeds and less ringing, but introduces more resistance and potential elasticity in the filament path. Bowden setups work well with rigid filaments like PLA and PETG but can present challenges with flexible materials like TPU.

Brim

A brim is a modified type of skirt (It is a bed adhesion setting in slicer software. Navigate to ‘S’ section of this article to know about Skirt). It is similar to a skirt but it is attached to the outer surface of the object on its first layer. It is similar to the brim of a hat. It serves the purpose of increasing the surface area of the print thus avoiding warping or the layers at the corners. Since it is connected only to the first layer, the brim can be easily removed after printing.

Brims are particularly useful for tall, narrow objects that might topple during printing. A brim width of 8-10mm is typically sufficient for challenging prints. For clean removal, scoring along the edge where the brim meets the part with a sharp craft knife before attempting removal makes the brim peel away cleanly without damaging the print.

Build Chamber

Build chamber is the space where the actual printing process occurs. The chamber envelops everything around the build plate, print head, guide rails and lead screw and in some cases even the filament. In high-end 3D printers, the build chamber is heated or even filled with an inert gas.

Build Plate

Build Plate, also called as ‘Build Platform’ or ‘Print Bed’ is the plate on which the extruder deposits the material in successive layers to form the object. In case of resin printing, the build platform is dipped in resin and it moves in the Z-direction as the cured material sticks to it.

C

C3DP (Construction 3D Printing)

C3DP, or Construction 3D Printing, refers to the application of additive manufacturing technologies in the construction industry. It involves using large-scale 3D printers to create building components or entire structures by extruding construction materials (typically specialised concrete mixes) layer by layer.

This technology offers significant advantages in construction speed, design freedom, waste reduction, and labour costs. Notable examples include the 3D printed offices in Dubai, residential buildings in China, and bridge structures in the Netherlands and even a school in India.

The technology is seeing rapid adoption in various parts of the world an so is a recent addition to our 3D printing glossary.

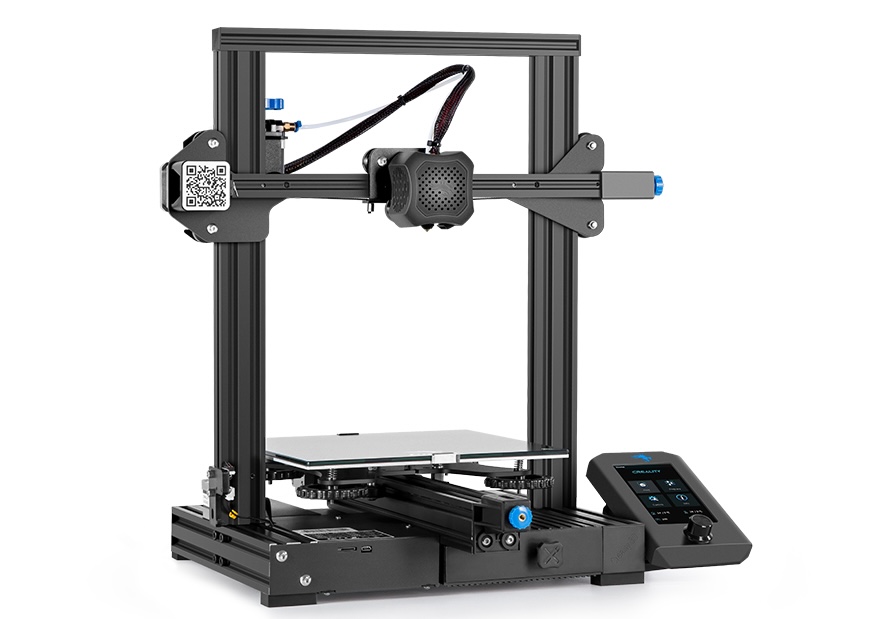

Cartesian Printer

These are the most common type of 3D printers. Cartesian refers to the co-ordinate system used by the printer to move the print head and the build plate. In these printers, there are three rails corresponding to each axis (X, Y, & Z). With the help of motors these rails guide the print head and the build plate to move as per the geometry of the model and print the object. It is relatively easy to build a Cartesian type of printer. Ultimaker 3D printers are good examples of Cartesian Printers.

Charles W. Hull

Perhaps the most important person in the 3D printing industry without whom the 3D printing glossary is incomplete. Charles (‘Chuck’) Hull, an American Engineer, invented the Stereolithography Apparatus (SLA) and even patented the technology in 1984. He is also known as the father of 3D printing. He is the co-founder of 3D Systems, one of the largest 3D printing companies in the world.

Computer Aided Design (CAD)

Computer Aided Design (CAD) is the use of computer to create, modify and optimise the designs. A CAD file is the most essential requirements of 3D printing without which the process cannot proceed. Autodesk Inventor, Catia, SolidWorks, Fusion360 (cloud-based CAD software), etc.

CoreXY

CoreXY is a 3D printer motion system design where both X and Y movements are controlled by two stationary motors working in tandem. This design reduces moving mass, allows for higher speeds and accelerations, and improves positioning accuracy. Popular in high-performance printers, the CoreXY design has been increasingly adopted by manufacturers focusing on speed and precision. The rigid frame design and reduced moving mass allow for much higher accelerations than traditional Cartesian setups, though they are typically more complex to assemble and troubleshoot.

Curing

Curing is a term specifically used in resin 3D printing like in case of SLA and DLP printing. In resin printing, the liquid resin is photosensitive and hardens when exposed to UV light. This process of selective exposing the resin to UV light and hardening it is called as curing.

D

Danit Peleg

Danit Peleg is an Israeli fashion designer who created the world’s first customisable 3D printed jacket. It was launched in 2017 and was available for sale in limited quantities.

Delta Printers

These are the second most common types of desktop FDM 3D printers currently available. Delta printers refers to the co-ordinate system used by the printer to move the print head and the build plate. In these printers, there are three vertical rails, and each rail has an arm connected to the print head. These are slide up and down independent of each other to print the part. The most important advantage of Delta Printers is that they can print tall objects.

Digital Light Processing (DLP)

Digital Light Processing is an additive manufacturing technology which uses a light source to cure a photopolymer liquid resin to build an object. The process is closely similar to SLA 3D printing technology.

Digital Light Synthesis

Digital Light Synthesis is a proprietary 3D printing technology developed by Carbon 3D that builds upon traditional DLP printing with significant innovations. The process uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce parts with exceptional mechanical properties. Unlike conventional resin printing that builds objects layer by layer, Digital Light Synthesis creates objects continuously by projecting light through an oxygen-permeable window, dramatically reducing print times.

This technology is particularly valued in industries requiring high-performance, end-use parts such as footwear, automotive components, and medical devices.

Direct Drive Extruder

A direct drive extruder is an extrusion system where the extruder motor is mounted directly on the print head assembly, minimizing the distance between the drive gear and hot end. This configuration provides more precise control over filament extrusion and retraction, making it ideal for flexible filaments and situations requiring accurate flow control. The trade-off is increased moving mass, which can cause more ringing at higher speeds, though modern input shaping technology has largely mitigated this disadvantage.

Direct Ink Printing

Direct Ink Printing (DIP) is an additive manufacturing technique that uses a fluid dispensing system to precisely deposit material in a controlled pattern. Unlike FDM which requires thermoplastic filaments, DIP uses specially formulated liquid inks containing materials ranging from ceramics and metals to biological compounds and conductive materials. The process operates at room temperature, allowing for the incorporation of sensitive materials such as cells or proteins.

DIP is particularly valuable in biomedical applications, electronics manufacturing (for printed circuit boards), and in creating objects with complex material compositions.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering is an additive manufacturing technology for 3D printing of Metals. It is the most effective method to 3D print various types of metal materials. It is basically sintering, i.e. the laser selectively fuses the metal powdered particles together without heating it to its melting point.

Directed Energy Deposition

Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy (typically a laser, electron beam, or plasma arc) to fuse materials by melting them as they are deposited. Materials, usually in powder or wire form, are fed into the energy source’s focal point where they immediately melt and solidify. DED is particularly valuable for repairing or adding material to existing components, creating large metal parts, and functionally graded materials. The technology allows for higher deposition rates than powder bed fusion methods and can produce fully dense metal parts with good mechanical properties.

E

E3D

It is a UK based company which deals with providing toolkits for 3D Printing like hot-ends, nozzles, extruders, filaments and even printer parts. Their V6 hot end, released in 2014, became an industry standard, and their Revo system (introduced in 2021) offers a quick-change nozzle system that eliminates the need for tools when changing nozzle sizes.

EBM (Electron Beam Melting)

Electron Beam Melting (EBM) is an additive manufacturing process that uses a high-energy electron beam to melt metal powder in a layer-by-layer fashion. Unlike laser-based metal printing technologies, EBM operates in a vacuum and at high temperatures, which results in parts with minimal residual stresses and excellent mechanical properties. The technology is particularly valuable for titanium alloys used in aerospace and medical implants.

EBM typically produces parts with a slightly rougher surface finish than DMLS or SLM but offers advantages in terms of speed and reduced post-processing requirements for stress relief.

Elephant’s Foot

Elephant’s foot is a 3D printing defect where the bottom layers of a print appear wider than they should be, creating a flared base resembling an elephant’s foot. This is typically caused by the first few layers being squished too much against the print bed due to improper Z-offset, overextrusion, or bed levelling issues.

Solutions include adjusting the Z-offset slightly higher (usually by 0.05-0.1mm), reducing the first layer flow rate to 95%, or adding a small chamfer to the bottom edge of the model to compensate for this effect.

ExOne

This Pittsburgh based company is a technology leader for industrial grade additive manufacturing. It provides 3D printers, 3D printing services, and related industrial services in various sectors and applications. In 2021, ExOne was acquired by Desktop Metal, consolidating two major players in the metal additive manufacturing space.

Extrusion (w.r.t 3D printing)

The process of pushing the heated plastic filament through the print nozzle to deposit the melted material onto the build platform in the desired geometry in successive layers. Extrusion printers are most commonly known to everyone as Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF).

F

FDM / FFF

Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF) is the same technology with similar process and usage. The only difference is that Stratasys Inc. had trademarked FDM and as a result the makers of the RepRap Community popularised the name Fused Filament Fabrication (FFF) so the community could discuss about the technology without infringing the trademark. But even after the expiry of the trademark, the use of Fused Filament Fabrication is still prevalent.

The FDM/FFF technology uses plastic material in the form of a filament. This filament the pushed through the print head where it is heated to its melting point and the melted material is deposited onto the build platform in the desired geometry as per the model to be created. The Print head generally moves in the X-Y direction and the Build platform moves in the Z direction for Cartesian type of printers.

FDM/FFF printers remain the most accessible entry point for newcomers to 3D printing. Despite their apparent simplicity, mastering an FDM printer requires understanding the relationship between temperature, speed, and material properties. A common mistake for beginners is rushing to print at high speeds before understanding how this affects layer adhesion and detail quality.

Some of the popular Brands offering FDM/FFF 3D printer include Creality, Anycubic, Prusa, UltiMaker and Stratasys.

Filament

The material used in FDM/FFF 3D printing is called as a filament. The standard diameters for filaments are 1.75mm and 3mm. Many types of filaments are available for 3D printing with varying properties like strength, density, flexibility, etc. Most commonly used materials are ABS, PLA, PetG, Nylon, Glow-in-the-Dark, Carbon Fibre, HIPS, PVA, etc.

Proper filament storage is crucial, especially in humid climates. Filaments should be stored in airtight containers with silica gel packets. Materials like nylon or PETG are highly hygroscopic (moisture-absorbing), and even a few hours of exposure to humid air can lead to popping, stringing, and weak layer adhesion. A filament dryer or food dehydrator set to low temperature (around 50-60°C) can rescue damp filament and improve print quality.

Filament Runout Sensor

A filament runout sensor is a device that detects when a 3D printer runs out of filament or when the filament breaks during printing. When triggered, it pauses the print, allowing the user to load new filament and resume printing without starting over. Modern sensors also often detect filament jams or slippage.

The most basic sensors use a simple mechanical switch that’s triggered when filament is no longer present, while more advanced models use optical sensors that can detect not just absence but also filament movement issues. This inexpensive upgrade can save significant time, material, and frustration, particularly for long prints or when using partial spools.

G

G-Code

G-Codes are the Geometric Codes used in a CNC program. Since 3D printing also works on the CNC principle, g-codes are also important in 3D printing. These codes tell the tool to perform certain actions like rapid movement, AutoBed levelling, set extruder to absolute mode, move X/Y/Z to min endstops, etc.

Gantry System

A gantry system refers to the structural framework that supports and guides the movement of the print head in a 3D printer. It typically consists of linear rails, belts or lead screws, and stepper motors that allow precise positioning in multiple axes. The rigidity and alignment of the gantry system directly affect print quality and speed capabilities.

One of the biggest differences between budget and premium printers is gantry quality. Upgrades like linear rails and reinforced frames can noticeably reduce vibration artifacts at higher speeds. If experiencing inconsistent layer lines or dimensional accuracy issues, checking the gantry for loose bolts, belt tension, and proper alignment should be done before adjusting slicer settings.

Glass transition temperature

It is the temperature at which the thermoset polymer material transitions from a hard & glossy material to a soft, rubbery material. It is important to know this temperature to make material decisions for specific applications. The nature of the material at room temperature will help determine the correct material for the application.

H

Heat Bed

A heat bed refers to the build platform used in an FFF printer. A heat bed is essential to print with certain materials like ABS, PET, etc. It can improve the layer adhesion of the material with the bed and it can directly affect the print quality. The heat keeps the first layer of the plastic warm and thus avoids warping (as mostly found in ABS printing)

High-Speed 3D Printing

This term is probably one of the most recent additions to this 3D printing glossary. High-speed 3D printing refers to FDM printing at speeds significantly faster than traditional rates, typically above 100mm/s and often reaching 250-500mm/s. This is achieved through optimised motion systems (like CoreXY), advanced firmware features (input shaping), improved hot ends with higher melt zones, and lightweight toolheads. Since 2021, high-speed printing has transformed from a specialty niche to a mainstream feature.

The high-speed printing revolution that started largely with Bambu Lab has now spread and every major brand now has a high-speed variant in their line-up. A benchy that previously took 2 hours can now print in 15-18 minutes with comparable quality. However, high speeds require more careful calibration—flow rates, temperatures, and cooling become much more critical. For upgrades, focus first on hot end melt capacity and motion system rigidity before attempting speeds above 150mm/s.

Hot End

Hot End is commonly confused with extruders. It should be noted that an extruder is a ‘cold end’ because the filament is cold when it passes through the extruder.

The Hot End is the part where the filament is actually melted. The heat sink, cooling fan and the nozzle form part of the hot end.

A common troubleshooting area involves hot end jams. When filament gets stuck, check the heat break (the thin tube between the heat sink and heat block). Even a tiny bit of carbonized filament here can cause major problems. A “cold pull” technique—heating the nozzle to normal printing temperature, pushing filament through, then letting it cool to about 90°C before pulling firmly—can often clear blockages without requiring disassembly.

I

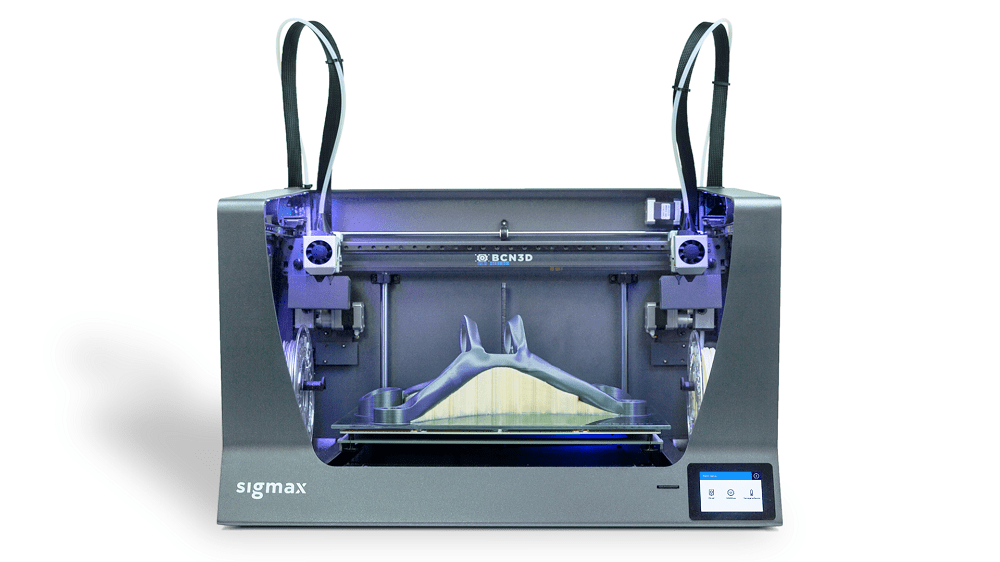

IDEX (Independent Dual Extruders)

IDEX stands for Independent Dual Extruders, a 3D printer configuration where two separate extruders can move independently of each other. Unlike fixed dual extruders, IDEX systems allow one extruder to park while the other prints, eliminating oozing problems and enabling unique print modes like duplication (printing two identical parts simultaneously) and mirror mode.

The ability to print support material with a different extruder than the main model allows for clean breaks between support and model without surface scarring. When considering an IDEX system, look for models with a purge wall or wipe tower feature to ensure clean colour transitions.

IGES

IGES (Initial Graphics Exchange Specification) is one of the oldest standardized file formats for exchanging CAD data between different software systems. Developed in the late 1970s and published as an ANSI standard in 1980, IGES files (with .iges or .igs extensions) store 3D geometry as wireframes, surfaces, and basic solid representations.

While still widely used in engineering workflows, IGES has limitations in transferring complex parametric data, assembly constraints, and material properties. Despite these limitations, IGES remains relevant in manufacturing pipelines where simpler geometry exchange is sufficient. In 3D printing, IGES files may need conversion to formats like STL before slicing, though some advanced industrial systems can work with IGES data directly.

Infill

In simple terms, Infill is the internal structure of the print. It can be completely hollow or fully filled with material or anything in between depending on the requirement of the final product properties. Normally, FDM prints are typically printed with 20% infill density.

Slicing software like Simplify3D, Cura, Slic3r and others offer varied types of infill patterns which offer better strength even in low density prints. Honeycomb is the most popular pattern which offers a good strength to the prints.

The infill pattern choice has a significant impact on print strength. For engineering applications, cubic and gyroid patterns offer the best strength-to-material ratio. When printing parts that will experience stress, a 3D honeycomb or cubic subdivision pattern at 15-20% provides better strength than a grid pattern at 30%—offering better strength with less material and shorter print times. For decorative items that won’t face mechanical stress, 10% zigzag infill might be sufficient to save material and time.

Input Shaping

Input shaping is a technique used in 3D printing to reduce ringing and ghosting artifacts (also called echoes) that appear on printed surfaces. It works by analysing the printer’s vibrations and then using algorithms to adjust the printer’s movements to cancel out these vibrations. First popularized by Klipper firmware, input shaping allows printers to achieve high-quality prints even at very fast speeds.

With input shaping enabled, printers can achieve print speeds of 100mm/s with the same quality previously achieved at 50mm/s. The improvement is most visible around sharp corners and text on prints—areas where vibration artifacts are typically most noticeable.

J

Josef Prusa

Josef Prusa is the CEO and founder of Prusa Research. He was a prominent contributor to the RepRap project (we will talk about this in a further section of this 3D printing glossary) and was the key person to design the Prusa i3 and Prusa Mendel. This became the base on which he built the foundations of his company.

Prusa Research has grown significantly, with their current lineup including the Original Prusa MK4 (released in 2023), the Original Prusa XL (a CoreXY machine with tool changing capability), the Prusa HT90 (a Delta-style 3D printer) and many others. The company also offers filaments, resins, Multi-Material Units, a slicer called PrusaSlicer and has a 3D model repository called Printables. They continue to be one of the most respected brands in the desktop 3D printing space.

K

Kapton Tape

Kapton tape is known for its thermal stability and was developed by DuPont for aerospace applications for electrical isolation. The RepRap community came up with a new application for this tape, as a bed surface for printing with ABS filament.

The purpose of the tape is to provide added bed adhesion to the first layer of print. This is achieved by spreading ABS juice (read ‘Acetone’ from the glossary) on top of the tape. With the juice and heat of the bed (around 70oC-90oC) the first layer sticks to the bed surface thus avoiding warping issues usually faced while printing with ABS filament. Additionally, it also protect the bed surface from damage.

Klipper Firmware

Klipper is an open-source 3D printer firmware that uses a Raspberry Pi or similar computer to handle the complex calculations needed for 3D printing, offloading this work from the printer’s mainboard. This architecture allows for more advanced features like input shaping, pressure advance, and smooth acceleration control. Klipper has gained immense popularity since 2020 for enabling significant speed improvements while maintaining or even improving print quality.

The setup process requires some technical knowhow, but the community support is excellent. This upgrade is particularly valuable for those frustrated by the speed limitations of stock firmware.

L

Layer Thickness

Layer thickness is simply the layer height of each successive layer of material added. The layer thickness defines the resolution of the printer in the z-axis. FDM printers generally have a layer thickness of 100 microns.

Layer height selection involves trade-offs between quality and time. Thicker layers (0.2-0.3mm) are recommended for functional prototypes and early iterations to save time, while fine layers (0.1mm or less) are better for final presentation pieces or parts with detailed top surfaces. Halving the layer height typically doubles the print time.

Linear Advance/Pressure Advance

Linear Advance (in Marlin firmware) or Pressure Advance (in Klipper firmware) is a feature that compensates for pressure buildup in the hotend during printing. It reduces oozing at the end of lines and under-extrusion at the beginning of lines by dynamically adjusting the extruder pressure based on printing speed changes. This results in more accurate corners and dimensionally precise prints.

Calibrating Pressure Advance involves running a standard calibration pattern to find the optimal K value (typically between 0.02-0.08 depending on filament). The impact is most noticeable on prints with text or sharp geometric features, where the improved extrusion control creates crisp, clean edges that would otherwise be slightly rounded or bulged.

M

Marlin

Marlin is an open-source 3D printer firmware developed for the RepRap project in 2011. Marlin is the most commonly used firmware and also adopted by many open-source 3D printer manufacturers like Ultimaker, Prusa Research, AlephObjects, etc. The current version, Marlin 2.1.2.5 (at the time of writing this article), includes support for 32-bit boards, automatic bed levelling, advanced features like Linear Advance, and improved user interface options.

Metal 3D Printing

Metal printing refers to 3D printing of metals. Metal 3D printing is achieved by DMLS, SLM, EBM, binder jetting and even recently some FDM technologies.

Metal FFF

Metal FFF (Fused Filament Fabrication) is an adaptation of standard FDM/FFF technology that enables the printing of metal parts using desktop-class equipment. The process uses filaments containing metal powder (typically stainless steel, copper, or bronze) bound with a polymer matrix. After printing, the parts undergo a two-stage post-processing: debinding (removing the polymer binder) and sintering (heating the part to near-melting temperatures to fuse the metal particles). This creates a solid metal part with properties approaching traditionally manufactured equivalents.

Metal FFF offers a more accessible entry point to metal 3D printing compared to technologies like DMLS or SLM, though with some trade-offs in density and mechanical properties. Several brands like BCN3D, Zortrax, UltiMaker, etc., now offer this capability.

MultiJet Fusion

MultiJet Fusion (MJF) is a powder-based 3D printing technology developed by HP that creates functional parts with exceptional mechanical properties. Unlike traditional powder bed systems that use lasers, MJF works by precisely applying fusing and detailing agents onto a powder bed, which are then activated by heat energy to create solid parts. This multi-agent process allows for precise control over part properties at the voxel level. MJF is known for its speed (up to 10 times faster than SLS), consistent mechanical properties, high reusability of powder, and ability to create detailed, functional parts.

The technology is particularly valuable for production-grade components in industries like automotive, medical, and consumer products.

MSLA (Masked Stereolithography)

MSLA, or Masked Stereolithography, is a resin 3D printing technology that uses an LCD screen to mask UV light, selectively curing entire layers at once. Unlike traditional SLA that uses a laser to trace each layer point by point, MSLA exposes the entire layer simultaneously, resulting in significantly faster print times. Most consumer-level resin printers today use MSLA technology.

The speed difference between SLA and MSLA is dramatic—prints that take 12 hours on an SLA machine can be completed in 3-4 hours with MSLA. However, MSLA comes with some trade-offs: slightly lower resolution than laser-based SLA and the need to periodically replace the LCD screen (typically every 2000-4000 hours of printing). For most users, especially those printing miniatures, jewellery models, or dental applications, the speed advantage makes MSLA the clear choice despite these considerations. If you want to know more, you can read our article on the evolution of resin 3D printing technology.

Modelling

Modelling is simply the use of computer systems to create, modify, analyse and optimise a 3D design in a soft format. Modelling is used to build accurate 3D models of required two-dimensional designs and later saved in relevant formats for forwarding it to the printing process.

General modelling and modelling for 3D printing are fairly different as some issues like watertight model, optimum wall thickness, understanding the 3D printing technology to be used, etc.

N

Nozzle

Nozzle forms a part of the Hot-end assembly. It is the end part which extrudes the molten filament onto the build platform. There are various types and qualities of nozzle and the choice is dependent on the materials to be extruded. Some of the most widely known nozzles are Stainless Steel, Brass & Olsson Ruby nozzle. Nozzles are used only in FDM/FFF 3D printing.

It is advisable to keep several spare nozzles on hand, as worn or damaged nozzles can cause frustrating print quality issues that are difficult to diagnose. For beginners, standard 0.4mm brass nozzles work well for most applications. For abrasive materials like carbon fiber or metal-filled filaments, hardened steel or ruby-tipped nozzles are recommended despite their higher cost.

Nozzle Clogging

Nozzle clogging occurs when debris, carbonized filament, or contaminants block the flow of material through the nozzle opening. This common FDM printing problem can range from partial clogs (causing under-extrusion) to complete blockages where no material extrudes.

Preventative measures include keeping filament in sealed containers with desiccant, regularly cleaning the nozzle with a brass brush when hot, and performing atomic/cold pulls with nylon filament after printing with filled materials. For stubborn clogs, heating the nozzle to about 20°C above normal printing temperature and then pushing through a length of clean filament often clears the blockage without disassembly.

Nylon

Nylon is a common 3D printing material used mainly in SLS technology in a powdered form. Nylon offers several benefits for 3D printing like strength, durability, high impact and abrasion resistance. It is suitable for printing of functional parts. However, it is highly hygroscopic and therefore be stored with adequate precautions.

O

OBJ

OBJ is a 3D file format widely used in 3D printing after the most common STL file. OBJ is considered more complex than an STL file since it also captures information related to colour, texture and some other properties. Generally, full-colour models like figurines and 3D selfies use OBJ files.

OctoPrint

OctoPrint is a free open-source software that allows you to control and monitor your 3D printer remotely. It was developed by the German software engineer Gina Häußge a decade ago in 2012. Since then, it is being constantly updated and upgraded by its active community of supporters and developers to include a wide range of features. It’s a powerful application that streamlines the printing process.

The latest versions of OctoPrint (1.11.x) have added significant improvements, including a streamlined interface, better plugin management, and enhanced timelapse features. While OctoPrint remains popular, newer alternatives like Klipper’s Mainsail and Fluidd interfaces are gaining traction, especially among users seeking high-speed printing capabilities.

On-Demand Manufacturing

On-Demand manufacturing is a new process of manufacturing wherein the goods are manufactured as and when they are required by the customer and not before-hand as in the case of traditional manufacturing methods.

3D printing has boosted this concept and offers the perfect solution by enabling faster production on time without any significant investment.

P

PEEK

PEEK or PolyarylEtherEtherKetone is one of the costliest material available in plastic 3D printing. It has superlative properties like excellent mechanical properties at high temperatures, phenomenal electrical, wear, chemical, and temperature resistance, flame retardant, very high durability & impact strength, etc. In some cases, it can even replace metal parts. This unique nature enables PEEK to be used in multiple industries like aerospace, medical, automotive, oil and gas industry, etc.

However, PEEK is not easy to handle. PEEK requires extremely high printing temperatures in the range of 350oC to 450oC with a 120oC heated bed. It is advisable to dry the PEEK material before printing. It is not as hygroscopic as nylon but the due to the cost it is preferable to dry the material and use to ensure good print quality. It is recommended that PEEK material should be printed on a PEI sheet which gives the best results.

Photopolymers

Photopolymers are the light-sensitive plastic materials used in resin 3D printers. These materials are in liquid state and on exposure to light, they are hardened (cured) to form the 3D object.

Polyjet

Polyjet technology is a direct 3D printing technique. It was patented by Object but after its merger with Stratasys, the patent is owned by Stratasys. Polyjet is a 3D printing technology which produces extremely smooth and dimensionally accurate parts with microscopic layer resolution of 0.1 mm. This technology is able to print with the widest range of materials available for any other technology.

Polylactic Acid (PLA)

Polylactic Acid (PLA) is one of the most commonly used FFF 3D printing filament. It is made from plant-based starch and are generally food-safe, they can easily bio-degrade and they do not give out toxic fumes like ABS.

PLA is an ideal starting material for newcomers to 3D printing. It’s forgiving, prints at lower temperatures, and doesn’t require a heated bed. However, PLA can become brittle over time, especially in humid climates. For parts that need to withstand mechanical stress or outdoor conditions, PETG is typically a better choice after mastering PLA. A common mistake is using PLA for functional parts that will be exposed to heat—anything above 60°C will cause PLA parts to deform.

Powder-Coated PEI

Powder-coated PEI (Polyetherimide) is a textured print surface created by applying powdered PEI to a metal sheet. The resulting textured finish provides excellent adhesion for a wide range of filaments while leaving a distinctive matte pattern on the bottom of prints. It has become the standard bed surface on many high-end printers, replacing smooth PEI and glass beds.

Textured powder-coated PEI provides exceptional adhesion for PETG and TPU without requiring adhesives, and the parts release naturally as the bed cools. The textured bottom surface it creates also helps hide first layer imperfections. When printing very small contact areas, reducing the first layer Z-offset slightly compared to smooth surfaces may be necessary to ensure proper adhesion.

Print Speed

It is the speed with which the printing takes place. The print speed can be controlled by using the slicing software. Till a fewyears ago, the typical printing speed ranged between 40-80mm/s. However, modern printers with direct drive extruders and input shaping can achieve much higher speeds between 250-500mm/s.

When pushing beyond these speeds, you will surely see a loss in print quality an so make sure you stay within the speed limits.

Prototype

A prototype is the first basic version of a final object generally manufactured to preliminarily test various parameters like shape, form, colour, texture, dimension, functionality, etc. A prototype helps to iterate the designs and correct any shortcomings in the final product.

Q

Qlone

Qlone is a free iOS App based 3D scanning software which lets you scan real-world objects with your mobile. The scanned models can be exported in multiple formats like OBJ, STL, PLY, X3D. The best part is that the models can be directly uploaded to sites like Sketchfab, Shapeways cgtrader and even social media sites like Instagram and Facebook for sharing or printing. The scanning is free but exporting the models is chargeable. It now also offers a solution for dentistry called Qlone Dental Pro 3D Scanner.

R

Raft

A raft is a thin sheet of grid printed on the build plate. The part to be 3D printed is printed on top of this grid instead of directly on the build plate. Rafts are specifically useful while printing with ABS to avoid warping issues. It gives extra surface area for the print to stick to the plate.

Rafts use extra material and time, and often leave a rough texture on the bottom surface of prints. They are recommended primarily for three specific scenarios: when printing small parts with minimal bed contact (say like a table type part printed with its legs on the print bed), when using warping-prone materials like ABS, or when dealing with an uneven or damaged build surface. For most standard PLA prints on a well-levelled bed, a brim offers better results with less waste.

Rapid Prototyping

Techniques used to rapidly manufacture a prototype is called as rapid prototyping. 3D printing was specifically developed to be the technology to rapidly manufacture prototypes so it can help faster iterations and faster modifications and less rejections in the final product.

RepRap

RepRap is short for Replicating Rapid-prototyper. During the mid-2000s, University of Bath, England started a project called as the RepRap Project to develop a low cost 3D printer which could replicate itself, i.e., print its own components. The RepRap project as an open source project and all of its designs are released under a free software license. Over the years it has expanded to form a big community.

Resin

The photopolymer materials used in Vat Photopoymerisation 3D printing technologies like SLA, DLP and CLIP are called as Resins.

Retraction (only relevant to FDM.FFF 3D printing)

Retraction is the process where the printer pulls back the filament slightly to prevent oozing or stringing when the nozzle moves without printing. The retraction distance (how far to pull back) and speed (how quickly to pull back) are critical settings for preventing stringing and blobs in prints.

Different materials require different retraction settings—PLA typically works well with 5mm at 45mm/s on a Bowden setup, while PETG may need 6.5mm at 25mm/s. For direct drive extruders, these distances are typically much shorter (0.5-2mm). If seeing fine strings between separate parts of a print, incrementally increasing retraction distance by 0.5mm until the problem resolves can be effective.

S

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powder bed fusion 3D printing technology. Polymer material is used in a powdered form which is melted at a particle level with a powerful laser to fuse adjacent particles to form a geometry of the specific layer. The process is repeated for each layer till the final object is printed.

Sensorless Homing

Sensorless homing is a technique that uses the electrical properties of stepper motors to detect when an axis has reached its mechanical limit, eliminating the need for physical endstop switches. By monitoring the back-EMF in the motor, the printer can detect when the motor stalls against a physical limit and use this as a homing position.

Implementing sensorless homing eliminates the mechanical endstops that occasionally fail or need adjustment, creating a cleaner and more reliable system.

The key to successful implementation is properly tuning the stall detection sensitivity—too low and the system risks missing the stall event, too high and it produces false positives during normal movement. Starting with conservative values and gradually decreasing until reliable stall detection occurs is recommended.

Sheet Lamination

Sheet Lamination is an additive manufacturing process that builds objects by bonding layers of material sheets together. The most common variant is Laminated Object Manufacturing (LOM), which uses paper, plastic, or metal sheets coated with adhesive. Each sheet is cut to the desired shape (typically by a laser or knife), then bonded to the previous layer using heat and pressure. The process continues layer by layer until the object is complete.

Sheet Lamination offers advantages like low material cost, the ability to create large parts quickly, and no need for support structures. It’s particularly useful for visual models, architectural prototypes, and creating full-colour objects when using coloured paper sheets.

Silent Stepper Drivers

Silent stepper drivers are advanced motor controllers (like TMC2209, TMC2226) that use sophisticated algorithms to control stepper motors quietly while maintaining precision. They significantly reduce the noise level of 3D printers by using techniques like StealthChop, which smooths the current delivered to the motor. These drivers also often offer features like sensorless homing and improved microstepping.

Upgrading from standard A4988 drivers to TMC2209 drivers can transform a noisy machine into a whisper-quiet one that can run overnight without disturbing the household. Beyond the noise reduction, improved print quality is often observed—the smoother motor control results in fewer artifacts on prints. This is one of the most impactful upgrades for anyone bothered by their printer’s noise.

Skirt

A skirt is an outline printed around the model but not connected to the model. The skirt is printed before the actual printing starts. This serves two purposes, first, it enables priming of the extruder to ensure that material has a smooth flow and second, it is a check before the printing whether the material is sticking to the build plate or not. This can signal the possible causes like bed adhesion, bed levelling, nozzle and bed distance, etc.

Slicing

Slicing is the process of dividing a CAD model into subsequent slices or layers of two-dimensional geometry and converting the CAD model into 3D printer readable format. The sliced model is saved in a G-Code (Geometric Code) format. The 3D printer reads the geometric codes and prints as per the geometry.

Slicing is where the real magic happens in 3D printing. The slicer functions as the translator between a design and the printer. Many print failures occur not because of hardware issues, but because of suboptimal slicing settings. Understanding key settings like wall thickness, infill pattern, and support density is crucial for successful prints. Creating a test model with various features (overhangs, bridges, thin walls) and experimenting with different settings helps build a personal “settings library” for different types of prints.

STEP

STEP (Standard for the Exchange of Product Data), also known as ISO 10303, is an international standard file format designed for exchanging 3D CAD data between different software platforms with high fidelity. STEP files (with .step or .stp extensions) preserve precise geometry, assembly structure, material properties, and in some cases, parametric information. Unlike STL files which approximate surfaces with triangles, STEP maintains exact mathematical representations of curves and surfaces, making it valuable for engineering applications where dimensional accuracy is critical.

STEP has become the preferred format for CAD data exchange in aerospace, automotive, and other precision industries. For 3D printing purposes, STEP files typically need conversion to STL or other mesh formats before slicing, though some advanced industrial systems can work directly with STEP data.

Stereolithography (SLA)

Stereolithography (SLA) is the world’s first patented 3D printing technology. These printers use a UV laser which is flashed on the resin contained in a tank. On exposure to UV light, the resin hardens. The hardened resin is built up layer by layer to form the final object.

STL

STL is short for Standard Tessellation Language. A CAD design saved in STL file format is easily readable by relevant slicing software used in 3D printing. An STL file only contains surface geometry information and does not store other properties like colour and texture. It is the most commonly accepted file format used in 3D printing.

A common issue with STL files is corruption or non-manifold geometry. Before sending any model to a slicer, running it through a mesh repair tool like Microsoft 3D Builder (built into Windows) or Meshmixer is recommended. Looking for holes, inverted normals, or intersecting faces can prevent printing failures and wasted filament.

Stratasys

Stratasys, Ltd. is one of the leading manufacturers of 3D printers and 3D production systems for direct digital manufacturing solutions. They are owners of a number of subsidiary companies and brands like MakerBot, Solidscape and GrabCAD (Online community of students, engineers, designers, and manufacturers for sharing of ideas and CAD models).

In recent years, Stratasys has continued to expand its portfolio, particularly in the industrial and medical sectors. In 2023, the company made headlines with its plan to merge with Desktop Metal, though the deal was ultimately terminated. Their current line-up includes the F series (FDM), J series (PolyJet), and H series (powder-based) printers, serving industries from aerospace to healthcare.

Support Material

In FDM printing, the support materials are mainly different that the print material. This helps in saving critical material as the support materials are of no use to the final part. The common support materials are PVA and HIPS.

In other 3D printing technologies, the support material remains the same as the printing material, although efforts are on to develop technologies that use different materials in powder bed fusion as well.

Support Structures

In 3D printing, the printing occurs in a layer by layer fashion and the basic premise is that the previous layer of print serves as a base for every successive layer to be printed. But while printing severe overhangs the previous layer is absent for the most part and in such cases the printer creates supports and prints the layer on top of this support considering these supports as the base. These are called as support structures and which can be printed in different patterns.

Several strategies can minimize the need for supports. First, orienting parts to minimize overhangs—sometimes rotating a model 45° can eliminate most support needs. Second, many slicers now have customizable support settings; using “support interface” layers with higher density just where the model meets the support makes them easier to remove without damaging the print. For PLA, a 60° overhang angle setting typically strikes a good balance between print quality and support material usage.

T

Thermoplastic Materials

Thermoplastic materials are used in FDM/FFF 3D printing. These materials are used in a filament form which are melted during the printing process. These materials can be remelted into a liquid multiple times. Common Examples are PLA, ABS, HIPS, PA, TPE, etc.

Thermosetting Materials

Thermoplastic materials are used in resin 3D printing. These materials are used in a liquid resin form which are hardened on exposure to a UV laser during the printing process. These are also called a Photopolymers as they react to light. These materials form irreversible chemical bonds on application of strong UV light as a result once an object is formed, it cannot be melted back to a resin form.

Thingiverse

Thingiverse is arguably the world’s largest and most popular 3D model repository and an intrinsic part of MakerBot. It is basically a design community for discovering, making, and sharing 3D printable things.

While Thingiverse remains popular, alternative model repositories have gained significant traction in recent years. Sites like Printables, Thangs, and Cults3D offer improved search functionality, modern interfaces, and often better creator incentives. Many designers now publish across multiple platforms or have moved away from Thingiverse entirely.

Topology Optimisation

Topology optimization literally means to optimise the topology of the design while keeping the strength and functionality of the design intact. It simply removes the excess material in a design without affecting the properties and functionality of the product to be manufactured.

Tree Supports

Tree supports are a modern support structure type that resembles branching trees, connecting to the model only where necessary and branching out from a few contact points with the build plate. Unlike traditional grid-style supports, tree supports use less material, are faster to print, and are much easier to remove while still providing adequate support for overhangs.

U

Ultimaker

Ultimaker is a Dutch 3D printer manufacturing company founded in 2011. It started out as open-source 3D printer manufacturer and then it expanded to build their own open-source slicing software Cura.

In 2022, Ultimaker merged with MakerBot to form UltiMaker, combining two major players in the professional desktop 3D printing market. Their current product line includes the S-series printers (S5, S6, S8, etc.), which feature dual extrusion, automated material handling, and advanced connectivity options. Their Cura slicer software remains one of the most widely used slicing programs, even by users of other printer brands.

UV Curing

UV Light is used in the 3D printing process in case of resin printers. The photopolymers used in resin printers are cured (hardened) on exposure to UV light to form the final object.

V

Vat

A vat is a container which holds the resin in case of resin 3D printing technologies like SLA and DLP.

Volumetric Flow Rate

Volumetric flow rate in 3D printing refers to the volume of filament that can be melted and extruded through the nozzle in a given time period, typically measured in mm³/s. Understanding your printer’s maximum flow rate is crucial for achieving high-speed printing without under-extrusion issues.

A simple test to determine a printer’s flow limits involves printing a 20mm cube with progressively increasing extrusion speeds until under-extrusion appears. Most standard hot ends with 0.4mm nozzles have a practical limit around 11-15mm³/s with PLA. For those seeking to print faster, upgrading to a larger nozzle (0.6mm) can nearly double this capacity without sacrificing much detail.

Voxel

A Voxel is simply a pixel with a volume & sometimes also called as a Volume Pixel. A voxel represents a three-dimensional space on a regular grid. It represents the tiniest element in a three dimensional object. Each individual voxel stores their relative location based on the position of the nearby voxels. They do not store absolute axis co-ordinates. They have the ability to store information related to the colour, opacity, density, etc.

W

WAAM (Wire Arc Additive Manufacturing)

WAAM (Wire Arc Additive Manufacturing) is a large-scale metal 3D printing process that uses welding technology to build parts layer by layer. The process feeds metal wire into an electric arc or plasma arc, which melts the wire and deposits it according to a predetermined path. WAAM is particularly valuable for producing large metal components (up to several meters in size) with relatively low equipment costs compared to powder-based metal printing systems.

The technology offers high deposition rates (up to 10kg/hour), making it suitable for industries like aerospace, marine, and heavy equipment manufacturing where large metal parts are needed. While WAAM produces parts with rougher surface finishes than other metal AM technologies, it can create fully dense parts with good mechanical properties at a fraction of the material cost and with minimal waste.

Warping

Warping is a phenomena occurring while 3D printing with certain materials. This generally occurs while printing with ABS. Warping basically is the thermal contraction of material as it cools down. Warping causes the corners of print to lose contact with the build platform and expose a gap between the print and the platform. This results in a failed print.

It can be avoided by using a heat bed and keeping the first layer of the print hot so it remains stuck to the bed.

A reliable approach to prevent warping, even without an enclosure, includes thoroughly cleaning the bed with isopropyl alcohol, applying a thin layer of ABS slurry (ABS dissolved in acetone) or a quality adhesive like Magigoo, setting the bed temperature to 110°C for the first layer and dropping to 100°C for subsequent layers. Turning off all cooling fans for the first 15-20 layers and ensuring there are no drafts in the room is crucial. For large prints, adding a “draft shield” (a single-wall perimeter around the print) in slicer settings creates a mini-enclosure that significantly reduces warping.

Watertight Model

Watertight models are those which are completely solid. In simple words, if the model were to be filled with water, then the water should not leak through the model. This is a watertight model. This may happen due to non-connection of edges and a line or a plane does not have dimensions in any of the three coordinates. Such models are non-printable.

X

X-Axis

It is the horizontal axis of a coordinate system. In most of the FDM 3D printers, the extruder moves in the X-axis. In 3D printing, the X-axis represents the horizontal right-left movement.

Y

Y-Axis

It is the vertical axis of a coordinate system. In most of the FDM 3D printers, the extruder moves in the Y-axis. In 3D printing, the Y-axis represents the horizontal front-back movement.

Z

Z-Axis

Finally, ending the 3D printing glossary with this last term. In a coordinate system, the Z-axis is also oriented in a vertical position. In most of the FDM 3D printers, the bed moves in the Z-axis. In 3D printing, the Z-axis represents the vertical up-down movement.

Share Your 3D Printing Knowledge

This 3D printing glossary represents an ongoing effort to make 3D printing more accessible to everyone in India’s growing maker community. As the technology evolves rapidly, so does the terminology surrounding it.

Have we missed a term you frequently encounter? Is there a technical concept you’d like clarified further? Or perhaps you have a practical tip to add to one of the definitions? Feedback is welcome through comments below or through Manufactur3D’s social media channels. User input helps keep this resource current and valuable for beginners and experts alike.

Learning 3D printing is a journey, and sharing knowledge strengthens the community. Together, we can continue building India’s presence in the global 3D printing landscape.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.