Amuse3D, the Chennai based 3D printing service provider, has established itself as India’s #1 Serial Production Partner for HP Multi Jet Fusion (MJF) 3D printing technology, offering comprehensive manufacturing solutions that bridge the gap between prototyping and serial production. With their state-of-the-art facility in Chennai combining HP MJF 3D printing and injection moulding capabilities under one roof, they’ve positioned themselves as a unique end-to-end manufacturing partner for industries where performance and compliance matter most.

Amuse3D operates through its 50,000 sq. ft. factory housing 4 HP MJF 3D printers, with the latest being 5620 model with process control, injection moulding machines, automated paint booths, advanced quality control systems, and certifications for both ISO 9001:2015 and IATF 16949:2016.

Amuse3D enjoys a wide variety of clients from aerospace, defence, drone manufacturing, automotive, and medical device industries and collectively it delivers more than 3 million parts across 850 customers worldwide annually.

The Move from Prototyping to Serial Production

The additive manufacturing industry has undergone significant evolution from its simple origin as a rapid prototyping solution to now being able to manufacture end-use parts. Companies are now leveraging the technology to ideate, prototype, and iterate faster to build new products and take them to market faster than ever before.

Additionally, 3D printing is not only a prototyping tool but it has also evolved into an end-use manufacturing technology that is used by a wide variety of industries from automotive to space, and from Drones to MedTech. The ability to rapidly and accurately manufacture functional end-use components with properties comparable to traditionally manufactured parts is taking the technology from simple prototyping to even mass production.

The economics are quite clear now: for production runs of less than 10,000 units a year, traditional tooling isn’t always the best choice. But these amounts are too big for regular 3D printing services that are mainly for making prototypes. Amuse3D fills this gap by running several HP MJF systems at the same time, which gives them the throughput they need for real serial production while still being able to change designs between batches.

Amuse3D – Post-Processing & Finishing at Production Scale

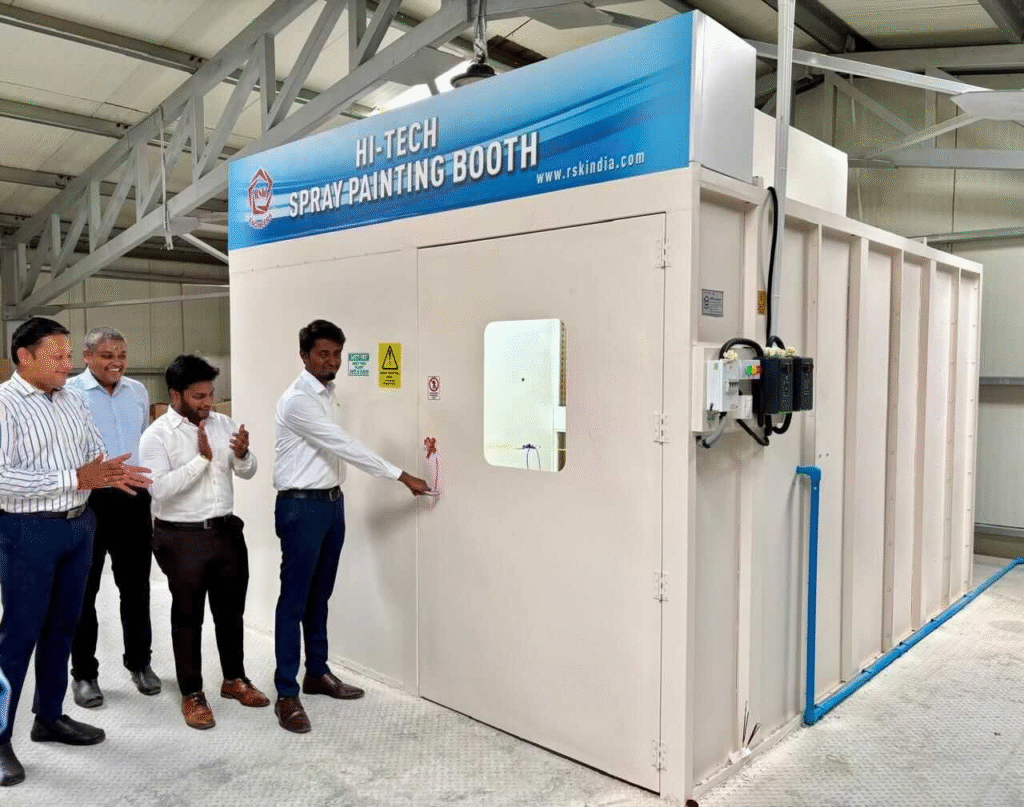

When the MJF technology operates at scale, the post-processing and finishing also has to keep up. From a basic painting setup to support prototyping in 2022, to now installing a large hi-tech spray painting booth, Amuse3D is taking post-processing to scale as well.

It is already acknowledged that 3D printed parts require some amount of post-processing and finishing operations to ensure they either have better strength or have a smooth surface finish. This stage is also as important as the 3D printing part and this is where most service bureaus lack the skill. Amuse3D has ensured this stage is not ignored.

Their paint booths are ready for automation and can handle hundreds of parts every day with the same high quality, whether it’s a simple matte black finish for car interiors or specialised coatings that can withstand chemicals for specific use cases.

For surface finishing, the team used a multi-stage process for a recent aerospace client that made air intake parts. The process includes vapour smoothing, sealing, and selective surface texturing. These treatments make the surface smoother, from say Ra 10–12 μm to less than Ra 3 μm. For aerodynamic requirements this process is highly essential.

Every part is also checked by a CMM (Coordinate Measuring Machine), and for each batch, they get a detailed report. This is something that most clients need for compliance documentation.

Certifications and compliance for important industries

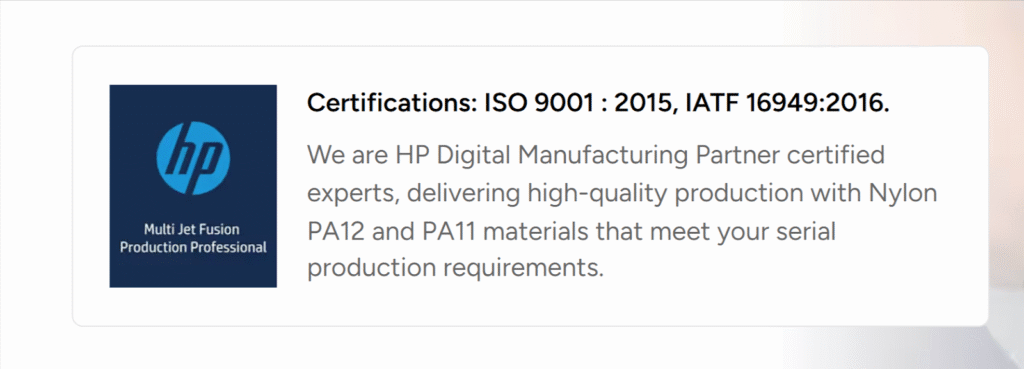

Amuse3D also holds two international quality certifications – ISO 9001:2015 and IATF 16949:2016 certifications. This enables them to offer quality management and traceability at scale. These certifications are fundamental to serving critical industries like space, defence, aviation, automotive, and more.

ISO 9001:2015

The ISO 9001 is a globally recognized standard for quality management. Implementing ISO 9001 means the organization has put in place effective processes and trained staff to deliver flawless products or services time after time. It is a mark of excellence in quality management.

IATF 16949:2016 for Automotive Excellence

The IATF 16949:2016 is also a global quality management standard for organisations across the global automotive industry. It was established by Automotive Industry Action Group (AIAG) through which one can gain the certification.

Compliance matters significantly in aerospace, automotive, and medical device manufacturing, where regulatory requirements govern every aspect of production. These industries require comprehensive documentation including dimensional reports, Certificates of Analysis (CoA), and complete process traceability.

HP MJF Uses in the Real World Across Many Fields

3D printing, especially MJF technology has use cases in many sectors and of them the ideal ones are in:

Aerospace and defence applications:

HP MJF technology has strong applications in aerospace and defence 3d printing sectors and it is known to print lightweight housings, brackets, and UAV structural parts. These components benefit from complex geometries and excellent strength-to-weight ratios, critical for applications where weight reduction directly impacts performance.

Automotive applications:

The automotive 3d industry also uses MJF 3D printing for interior components and functional end-use parts, from air vents and dashboard elements to under-hood applications. It is also ideal to produce a limited number of custom parts for limited edition models or for on-demand spare parts.

Medical device applications:

Medical device manufacturing is another strong application area for MJF technology. The Nylon material is perfect for durable, biocompatible housings that can move from prototype to production seamlessly. These applications range from portable diagnostic equipment enclosures to surgical instrument components

Conclusion

Amuse3D has emerged as India’s leading serial production partner for HP MJF 3D printing. It not only has the most number of MJF 3D printers in India but also has evolved into a full-fledged manufacturing powerhouse with the expansion of its capabilities to include injection moulding, post-processing facility along with the two global quality certifications.

It not only offers prototyping but also serial production capabilities and caters to a wide array of sectors and applications.