If you’re reading this, you’re likely searching for ways to eliminate or hide layer lines in 3D prints. I’ve been 3D printing for over six years now, and I’ve learned that layer lines are neither good nor bad—they’re simply a characteristic of FDM printing. However, I completely understand the desire for smoother, more professional-looking prints that don’t say “I am 3D printed!”

While perfect smoothness might be challenging to achieve directly from the printer, I’ve discovered several clever techniques to hide layer lines without extensive post-processing. If you’re more interested in actually reducing layer lines through printer settings and calibration rather than just hiding them, be sure to read our detailed guide on 10+ ways to reduce layer lines in 3D prints.

Over the years, I’ve experimented with numerous approaches (some of them on my own and some that makers have posted on Reddit and other forums), and in this updated guide for 2025, I’ll share the most effective tricks I’ve personally tested.

What are Layer Lines?

Layer lines are the visible perforations or parallel lines that appear on the surface of objects printed using most 3D printing technologies. This is most pronounced in Fused Deposition Modelling (FDM) technology (all my tips are related to this technology). These lines form when the printer deposits successive layers of material, typically ranging from 0.1mm to 0.3mm in height (in FDM), to build up your model layer by layer. These are clearly visible on the outer surface of the 3D printed part.

Think of it like building a wall with Lego bricks—no matter how precisely you place each brick, you’ll still see the horizontal lines where they join. Similarly, in 3D printing, each layer of filament creates a slight ridge where it meets the next layer.

Several factors influence how prominent these lines appear:

- Layer height: Thinner layers (0.1mm) produce less visible lines than thicker layers (0.3mm).

- Filament type: Some materials show lines more than others.

- Print speed: Faster printing can exacerbate visible lines.

- Printer calibration: Well-tuned printers produce more consistent layers.

- Model geometry: Curved or sloped surfaces tend to show layer lines more obviously than vertical walls.

While traditional post-processing methods like sanding, filling, and painting can eliminate layer lines, these approaches are time-consuming and require additional equipment. The techniques I’ll share focus on hiding layer lines during or immediately after the printing process with minimal effort.

Tips and Tricks to Hide Layer Lines in 3D Prints

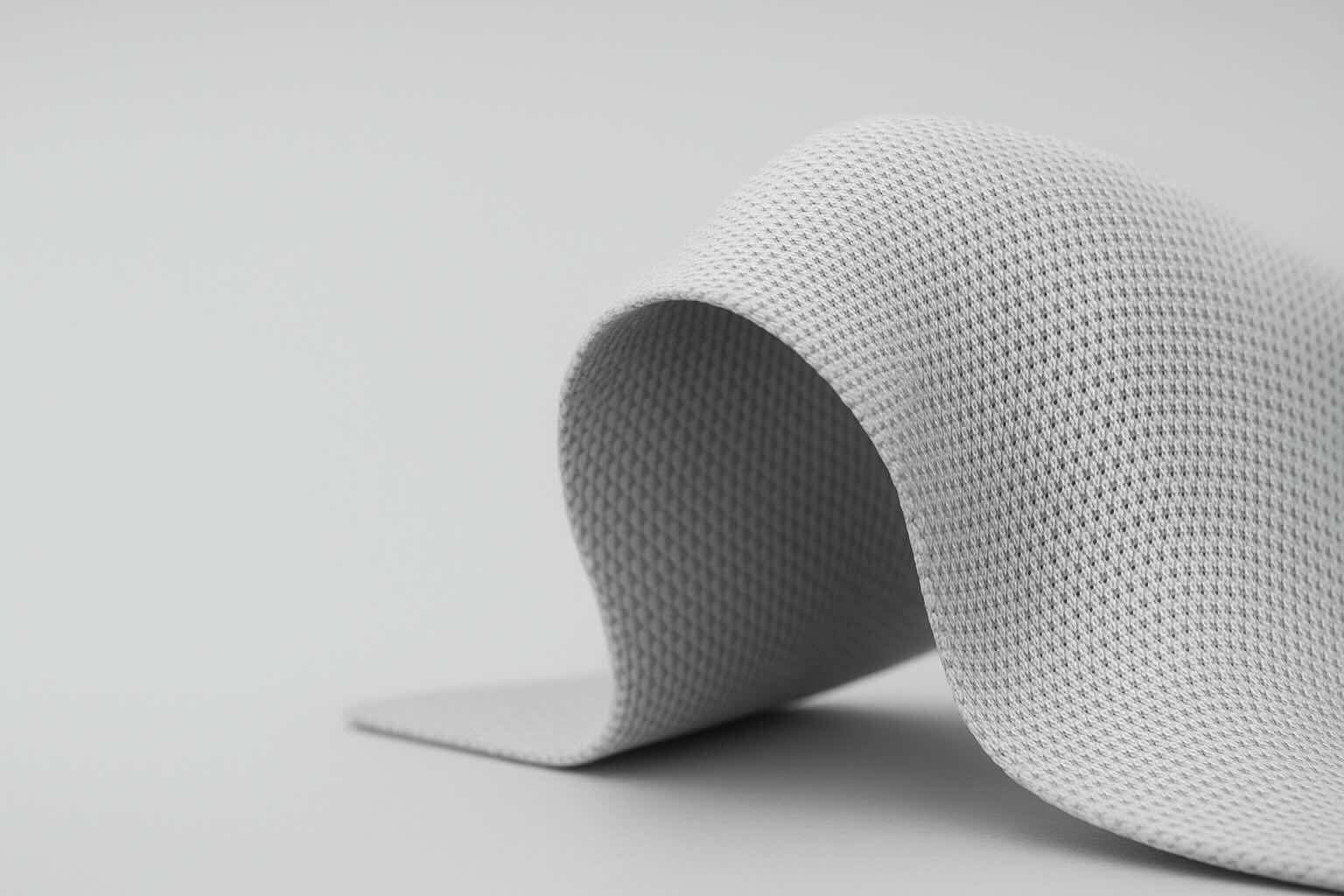

Make use of Textures

One of my favourite techniques is incorporating deliberate textures into my models. I’ve found that textures not only serve functional purposes but also brilliantly disguises layer lines. The layer lines simply blend into the intentional texture and then it becomes hard to notice the lines.

Textures work because they break up the visual continuity of layer lines, making them indistinguishable from the intended surface pattern. They also add character to your prints that smooth surfaces simply can’t match.

You can create textures in several ways:

- Design them directly in CAD software like Fusion 360, Blender, or ZBrush

- Use texture generators in slicers like PrusaSlicer or Cura

- Apply patterned infill to the outer layers in IdeaMaker or SuperSlicer

I particularly recommend trying the “Surface Texture” feature in Raise3D’s IdeaMaker slicer, which allows you to apply various patterns directly to your model without modifying the original file.

In Cura, you can use the “Fuzzy Skin” feature on outer walls to create a textured surface that completely obscures layer lines. By setting the Fuzzy Skin Thickness to 0.1mm and Point Distance to 0.5mm, you can create a fine texture that looks intentional rather than a printing artifact.

Make better Material Choice

Material selection might not stand out as an obvious trick but it is a clever way to hide layer lines in 3D prints. I’ve tested dozens of filaments specifically for their ability to mask layer lines, and certain types consistently outperform standard solid-colour filaments.

Try printing your parts with materials like Marble-fill, Wood fill, and other similar materials and you’ll be surprised how well it masks the layer lines.

Some filament types that excel at hiding layer lines include:

- Marble-filled PLA: The random flecks break up the visual pattern of layers (you can check out brands like Polymaker PolyTerra, ELEGOO or FibReel).

- Wood-filled PLA: The natural texture and matte finish obscure layer lines (you can check out brands like eSUN, colorfFabb, etc.).

- Speckled/granite filaments: Similar to marble but with different colour patterns.

- Metal-filled filaments: Especially after a light polish with steel wool.

Make use of Layer Lines as a design feature

Rather than fighting against layer lines, sometimes one needs to embrace them as a deliberate aesthetic element. In some products, the layer lines can be the element that makes the product stand out. Imagine a decorative lamp where the layer lines can create beautiful light diffraction patterns when illuminated from within.

This approach requires a mindset shift—instead of seeing layer lines as flaws, consider them unique characteristics of 3D printing that can enhance certain designs. You can look to rethink how you orient the model so layer lines may follow natural contours or patterns or you can even design the model with the layer lines in mind and consider having pronounced layer lines by printing the part with a higher layer hight.

As an extreme example, most construction 3D printed houses purposely keep expose the printed layers of some the walls or even some rooms to add to the uniqueness of the construction. This adds to the intrigue and sets the construction apart from the regular ones.

Vase Mode / Spiral Mode

Vase mode (also called spiral mode or spiralize outer contour) has been a game-changer for creating smooth decorative objects. When I printed a set of desktop planters using vase mode on my Creality Ender 3 S1 Pro, the results were remarkably smooth—almost indistinguishable from injection-moulded products.

In vase mode, the printer creates the outer shell in one continuous spiral movement rather than discrete layers. The nozzle gradually rises in a continuous motion as it traces the perimeter, eliminating the traditional layer-to-layer transitions that cause visible lines. This continuous motion ensure there are no lines in z-direction.

However, vase mode does have limitations where the models have to be simple in structure, the prints have to be single-walled due to which these parts can only be for aesthetic purposes, not for functional parts.

I recommend using vase mode for decorative items like vases, lampshades, and artistic models where strength isn’t critical. For best results, use a smaller nozzle (0.3mm or 0.4mm) and slightly slower print speeds to ensure consistent extrusion.

Adaptive Layer Height

One technique I’ve been using extensively since the last couple of years is adaptive layer height. This feature lets you define different regions of your model to be printed with a different layer height and automatically smooth the transition between them. This can result in significantly shorter print times with minimal sacrifice to the print quality. This features is available in slicers like PrusaSlicer, Cura, and SuperSlicer.

According to Prusa Research’s detailed guide on variable layer height, this technique can reduce print time by up to 30% while maintaining detail where it matters most.

The genius of this approach is that it applies thinner layers only where they provide visual benefit—on curved surfaces and detailed areas—while using thicker, faster layers on vertical walls where layer lines are naturally less visible.

To use adaptive layer height effectively:

- In PrusaSlicer: Enable “Variable Layer Height” and use the automatic or manual layer editing tools

- In Cura: Check “Adaptive Layers” and adjust the “Adaptive Layers Maximum Variation” (I recommend 0.04mm)

- Set your minimum layer height to about 40% of your nozzle diameter for best results

The results are particularly impressive on organic models like figurines, sculptures, and terrain pieces, where the varying layer heights follow the natural contours of the model.

Filament-Specific Techniques

Over the years, I’ve discovered that certain filament types have unique properties that can be leveraged to minimize layer lines. Here are some of my tried-and-tested approaches:

Silk PLA: When I print with silk filaments, I’ve found that increasing the temperature by about 5-10°C above standard PLA temperatures (I use 215-220°C) creates a more liquid flow that helps layers blend together better. The reflective nature of silk PLA filaments also disguises layer transitions, as I discovered when printing trophy models for a local competition.

Matte PLA: Filaments with matte finishes, like Polymaker PolyTera PLA or eSun Matte PLA, diffuse light rather than reflecting it sharply, which makes layer lines less noticeable. I printed a set of architectural models with Overture Matte White, and the layer lines were significantly less visible than with glossy filaments.

ColorFabb Vertigo Grey: This specialty filament has a unique visual effect that creates an optical illusion, making layer lines almost disappear from certain angles. It’s pricier than standard filaments, but for showcase pieces, I’ve found it well worth the investment.

Temperature Gradients: For taller prints, I sometimes program a gradual temperature increase as the print progresses (for example, starting at 205°C and slowly increasing to 215°C). This creates a subtle gradient effect that makes layer transitions less obvious, a trick I learned after much experimentation with a 30cm tall lighthouse model.

Strategic Orientation and Slicing

The way you orient your model on the print bed can dramatically affect how visible layer lines are. You can save numerous hours of post-processing simply by strategically orienting the model. For example, I read in a Reddit post once that one Redditor designed a Chess set where he oriented the pieces so that the layer lines followed the natural contours of the pieces. By placing the queen at a 45-degree angle to the build plate, the layer lines appeared as intentional rings around the piece rather than obvious steps.

Some interesting orientation strategies:

- Position curved surfaces so they print at angles between 30-60 degrees to minimize stair-stepping

- Orient the most visible faces of your model vertically when possible

- Place detailed features so they don’t align with the Z-axis

Conclusion

After years of experimenting and reading about the various techniques, I’ve come to appreciate that hiding layer lines doesn’t have to involve tedious post-processing. The methods I’ve shared have helped me create prints that have ‘hard to see’ layer lines. I strongly believe that one does not need to hide the fact that the part has been 3D printed but these techniques can help you in case you get parts that have pronounced layer lines which you wish to reduce or have aesthetic applications where the layer lines can be a distraction to observers.

The beauty of these approaches is that they work with the 3D printing process rather than fighting against it. Whether you’re creating decorative items, functional prototypes, or display models, these techniques can elevate your prints without adding significant time or complexity to your workflow.

I’d love to see how you apply these methods to your own projects! Share your results by tagging Manufactur3D on social media or sending us photos of your layer-line-free creations. And if you’ve discovered other effective techniques for hiding layer lines, please share them in the comments—I’m always looking to expand my 3D printing toolkit.

Which is more effective for hiding layer lines: reducing layer height or using specialty filaments?

In my experience, specialty filaments like marble or wood-fill PLA provide more dramatic improvements with less print time impact than simply reducing layer height. A marble PLA print at 0.2mm often looks smoother than a solid colour PLA at 0.1mm, while printing twice as fast.

Do I need an expensive printer to implement these layer-hiding techniques?

Not at all! I’ve successfully used all these methods on budget printers like the Ender 3 and even Wanhao Duplicator i3 mini. The techniques actually work on any FDM printer, regardless of price point.

Will these methods affect the structural integrity of my prints?

Most won’t impact strength significantly. However, vase mode creates single-walled prints that are more delicate, and some textured surfaces may create stress concentration points. For functional parts, I recommend using the material selection and adaptive layer height methods rather than vase mode or heavy texturing.

What’s the quickest method to hide layer lines for a last-minute project?

Vase mode for simple objects or marble filament for complex ones. Both methods can produce great results straight off the printer with no post-processing needed.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, follow us on Facebook, LinkedIn and Twitter.