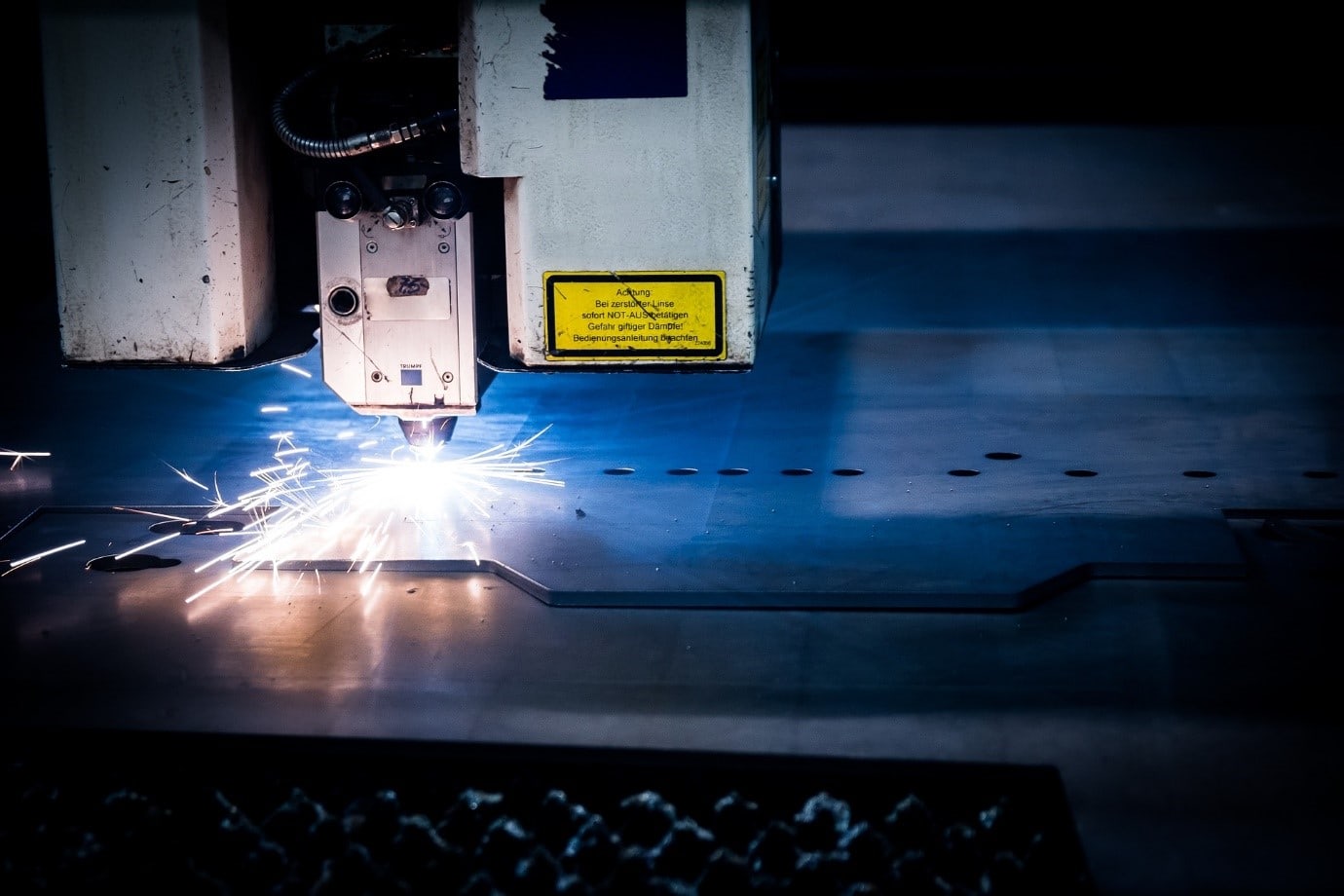

CNC machining, clubbed with 3D printing, represents a more efficient approach to production and is fast becoming the method of choice in a wide variety of industries. By instructing a lathe, milling machine or one of many other machines to perform its processes automatically, with input from a CAD software system, the manufacturing process is significantly improved in terms of speed, efficiency and cost-effectiveness. Use in the automotive and aerospace industries, by heavy industry, in the medical world and more, CNC and 3D printing are the way to go, but how do you ensure you are keeping your costs as low as possible?

There are a number of ways you can reduce CNC machining costs, some of which take place during the machining processes, and we will look at those first before we talk about how to make 3D printing more cost effective. Visit Rapid Direct for more information.

Reducing CNC Machining Costs

Choose the Right Materials

If you are machining metal pieces, it might be worth checking out whether there is a cheaper metal you can use to produce your item. For example, some types of aluminium are considerably cheaper than stainless steel. Could your item be made from aluminium, rather than the expensive steel you are currently using? It depends upon the item itself, what it is used for and how much pressure or tension it is put under, but the massive cost difference makes it worth investigating.

Also, is the metal you are using the easiest to machine? Once again, steel is harder to machine that aluminium and therefore will take more time. More time means greater costs, so it follows that using the easiest to machine material makes a great deal of sense. These are cost-saving areas that need very careful consideration, but they will save you large amounts.

Simple Design

The advantages of using 3D CAD – computer aided design – software are plentiful, and one the most impressive is that a good designer will be able to see problems in the machining area during the design process. This means that the design can be simplified for production purposes, making it easier to create using the CNC method. CNC is also more accurate than traditional machining, so there will be less waste if the item is designed correctly. The in-built factor of elimination of human error is another cost reduction element that comes with CNC.

A massive bonus with CNC, and one that can help greatly with cost reduction, is that the machine is able to reproduce the same item repeatedly, without the need to be reprogrammed. If you have a repeat customer likely to order the same item on a regular basis, choosing to produce greater than the ordered quantity cuts down on set-up costs, and further reduces your operating costs.

You’ll also find that a CNC milling machine requires fewer operators to get the job done and, as it produces things faster, can therefore increase your productivity and yield without additional help. Whatever industry you are in, if manufacturing and production are part of the business you need to have a closer look at using CNC machining instead of the traditional methods you are currently using.

Reducing 3D Printing Costs

As CNC milling and 3D printing go hand in hand, the methods to reducing costs in each are similar. These are tips you can consider when you need to reduce 3D printing costs.

Hollow the Model

As with saving on material costs for CNC machining, so the same can be done with 3D printing. Unless your model needs to be solid, then the best way to save money on materials is to print it hollow. As long as you keep the wall thickness to the required level – that is around 1 to 3mm for plastics, for example – you will end up with the result you require, but with only the necessary raw material used.

The computer software you use to design your items and program the 3D printing machines will allow you to create hollow or solid objects, and you can also optimise your printing speed and method to suit, thus saving further money.

Also, where infill is required, keeping it to the bare minimum – that is where it remains structurally sound but does not require too much material – will further reduce your waste and materials cost. While on the subject of materials, it’s worth shopping around for the best deal on plastics, as this can vary greatly between suppliers and types.

Layer Height and Resolution

3D printing works by adding layer upon layer of the raw material, and the thinner the layers, the finer the finished result. This is the equivalent of resolution in standard printing. However, not every item will need such a fine result and it can be cheaper – as it is less complex and takes less time – to use thicker layers for those items that are perhaps not necessarily intended to be finely finished.

Time is one of the many adjustable factors in terms of 3D printing and in CNC machining, and anywhere that time can be saved is also money saved. This applies to set-up – which will be quicker when you are performing the least complex printing – as much as it does for the running time, so it is certainly worth considering how and where you can save time to cut back on costs.

Both 3D printing and CNC machining are cost-effective, efficient and modern methods of production that are rapidly becoming more widely utilised across varied industries, and the above are just a few of the methods that can be used to keep costs as low as possible.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D Printing. Visit our Global News page for more updates on Global 3D Printing News. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.